Welcome to the ultimate guide on how 98% transmittance AR (Anti-Reflective) glass is made. This guide will give you a detailed look into the manufacturing process of this high-quality product, which is an essential component in various devices ranging from cameras to display screens.

Brought to you by Tibbo, a leading professional manufacturer and supplier of custom glass products in China, we’ll take you behind the scenes of our advanced production process, illustrating our commitment to quality and precision.

The Manufacturing Process of 98% Transmittance AR Glass

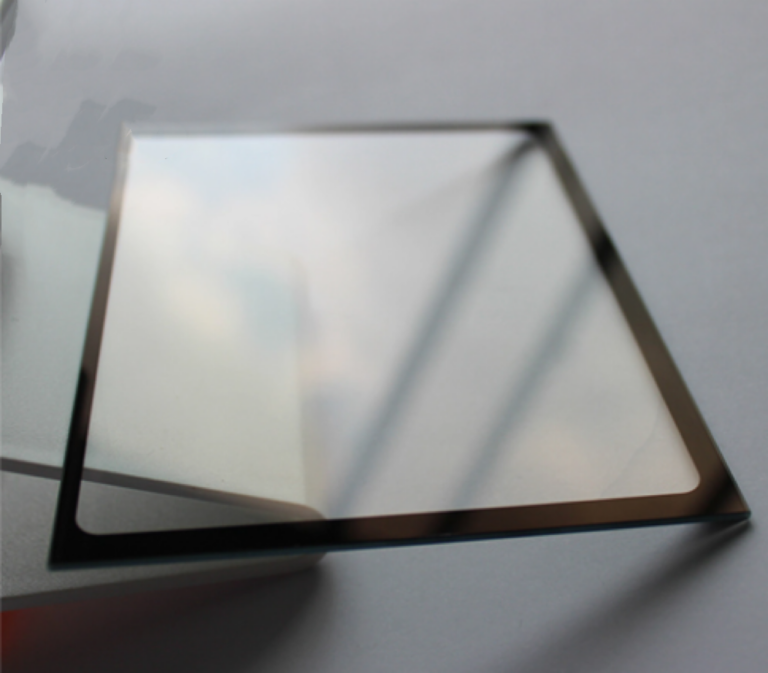

The journey of creating 98% transmittance AR glass begins with selecting high-grade raw materials. This quality control process ensures that the glass has the necessary strength and clarity to perform its function effectively.

Next, the glass undergoes rigorous grinding and polishing processes. At Tibbo, we use German high-end testing machines and Swiss high-end CNC machines to achieve precise results.

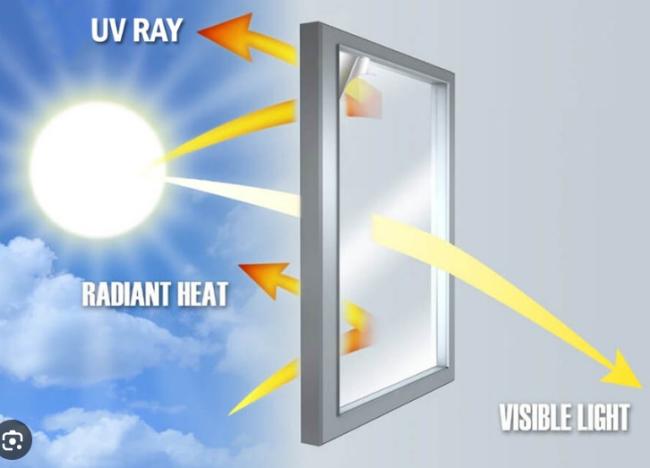

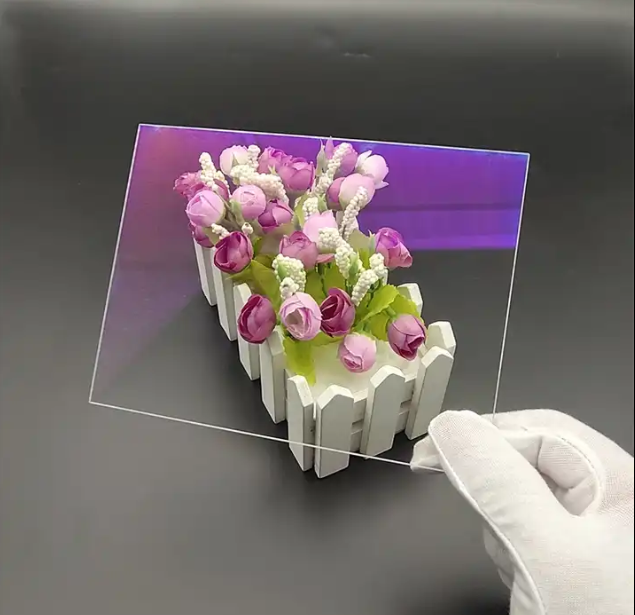

After the glass has been shaped and polished, it’s time for the crucial step: the AR coating. This critical process involves depositing layers of specific materials onto the glass surface. These layers are designed to minimize the amount of reflected light, thus maximizing transmittance to an impressive 98%.

Our AR glass is then subjected to a series of tests in our high-end laboratories. These tests are conducted using advanced coating testing equipment to ensure the glass’s durability, effectiveness, and quality meet our high standards.

Why Choose Tibbo’s 98% Transmittance AR Glass?

At Tibbo, we pride ourselves on our ability to produce high-quality glass products. Our strong hardware strength and advanced equipment enable us to maintain superior production standards consistently.

Not only do we have a large factory area, but we have also introduced a number of foreign equipment, including high-end testing machines from Germany, high-end CNC machines from Switzerland, and high-precision grinding machine processing equipment. Furthermore, our fully automated screen printing coating production line ensures the efficient and precise application of AR coating.

Our commitment to quality and excellence has earned us a reputation as a trusted B2B exporter. Our products are well-received not only in China but also in Europe, North America, India, Russia, the Middle East, and other regions.

Learn more about our manufacturing process in our blog post: How is R<1% AR Coated Glass Substrate Made: The Ultimate Guide.

Conclusion

At Tibbo, we specialize in manufacturing, producing, and exporting high-quality AR glass with 98% transmittance. We’re a vital part of the B2B supply chain, offering top-notch products that enhance the capabilities of various devices.

Whether you’re a business owner looking for reliable glass suppliers or a curious reader interested in the manufacturing process of AR glass, we hope this guide has provided you with valuable insights. Choose Tibbo, your trusted partner in delivering superior glass solutions.