Making strides in the glass manufacturing industry, Tibbo is proud to bring you a comprehensive guide on the creation of Anti-bacterial Glass. As a prominent figure in the B2B global export arena, our expertise is not just limited to manufacturing and production, but also extends to export capabilities. Our reputation as a leading, authoritative, and high-quality professional manufacturer and supplier from China is founded on these cornerstones.

What is Anti-bacterial Glass?

Anti-bacterial Glass, as the name suggests, is a specially treated type of glass that inhibits the growth of bacteria on its surface. This makes it an ideal choice for environments requiring high sanitary standards, such as medical facilities, food preparation areas, and touchscreen devices.

The Manufacturing Process of Anti-bacterial Glass

The production of Anti-bacterial Glass involves a series of carefully controlled steps. It begins with the selection of superior raw glass and includes stages of cleaning, coating with an anti-bacterial layer, curing, and final inspection.

Raw Glass Selection

The process commences with the selection of top-tier raw glass. The quality of the raw glass is pivotal, as it greatly influences the final product’s performance and longevity.

Cleaning

The chosen raw glass then undergoes a meticulous cleaning process to eliminate any dust particles, residues, or impurities that could interfere with the adhesion of the anti-bacterial coating.

Coating

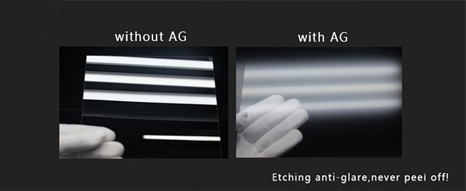

The clean glass is then coated with a special anti-bacterial layer. This layer is often nanometer-thin and is applied using innovative coating techniques under specific conditions. The coating grants the glass its unique anti-bacterial properties.

Curing

Following the coating process, the glass is subjected to a curing stage. This step solidifies the coating and ensures it is tightly adhered to the glass surface. The curing process often involves heating the glass to a precise temperature for a defined duration.

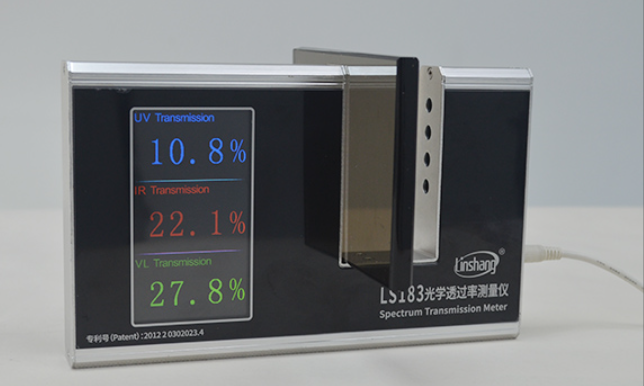

Inspection

The final step in the manufacturing process is a thorough inspection. This crucial step guarantees that the finished product meets the highest quality standards and exhibits the desired anti-bacterial properties.

Why Choose Tibbo for Your Anti-bacterial Glass Needs?

Tibbo was established in 2014 and has since paved its way to the forefront of the glass manufacturing industry. Our robust infrastructure includes a large factory area, state-of-the-art foreign equipment, high-precision processing machines, and a fully automated screen printing coating production line.

Our commitment to quality and excellence is reflected in our products, which are well-received not only in China but also exported to Europe, North America, India, Russia, the Middle East, and other regions. We offer customization options for dimensions, thickness, and coating types to cater to your specific needs.

For more insights about glass manufacturing, check out our previous guide on “How is AF Glass Made“. We look forward to serving your glass manufacturing needs. With Tibbo, you can always anticipate superior quality products, professional service, and a seamless B2B experience. Visit our product catalogue today to find your perfect glass solution!