Welcome to the world of glass manufacturing, where technology, art, and science intersect to create products of remarkable quality and durability. Our focus in this guide is on the production process of UV resistant toughened glass, a product that finds extensive use in numerous applications, from display screens to solar panels. As a leading manufacturer and supplier in China, Tibbo has carved a niche in the industry with its strong emphasis on quality, innovation, and customer satisfaction.

The Raw Materials

The journey of making UV resistant toughened glass begins with sourcing the finest raw materials. The primary component is silica sand. Other ingredients include soda ash, limestone, and dolomite. These materials are mixed together in precisely measured quantities to ensure the glass’s quality and properties.

The Melting Process

The mixture of raw materials is heated in a furnace at approximately 1500°C. This high temperature melts the mixture into a homogenous liquid, which is then cooled slightly to a molten state.

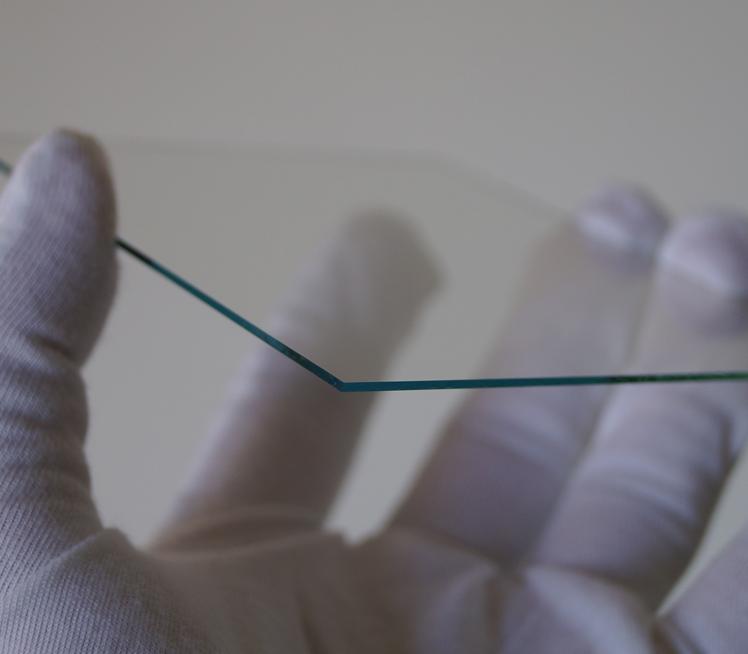

The Forming Process

The molten glass is poured onto a tin bath, where it floats on the surface due to the difference in density. This is known as the “float glass” process. The glass is cooled gradually in a controlled environment to prevent unwanted stress and to improve strength.

The Toughening Process

The formed glass sheet is subjected to a toughening process, also known as tempering. This involves heating the glass to a temperature near its softening point and then rapidly cooling it. This process increases the strength of the glass by up to five times compared to untempered glass.

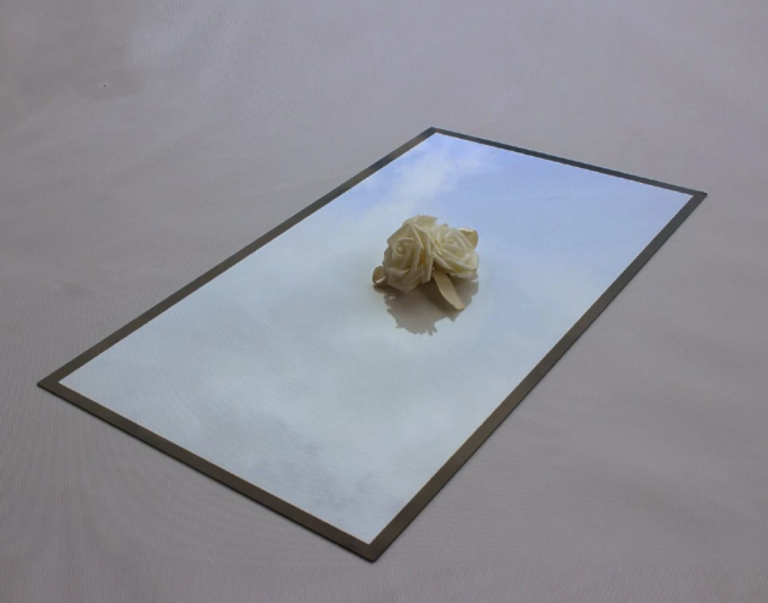

UV Resistant Coating

The toughened glass is then coated with a UV resistant layer. This is usually achieved by a process called sputter-coating, where a thin film is deposited on the glass surface. This UV coating reduces the amount of harmful ultraviolet rays that pass through the glass, making it ideal for applications exposed to sunlight.

Quality Assurance

At Tibbo, every piece of glass undergoes rigorous quality checks to ensure that it meets the high standards set by the industry and our company. Our state-of-the-art testing machines and fully automated production line ensure the consistent quality of our products.

The process of making UV resistant toughened glass is an intricate one, requiring a perfect blend of precise machinery and human expertise. At Tibbo, we pride ourselves on our ability to manufacture, produce, and export high-quality glass products that cater to the diverse needs of our B2B clientele.

Interested in learning more about the fascinating world of glass manufacturing? Check out our previous blog post on how scratch-resistant and UV resistant glass is made.

We are Tibbo, your reliable partner in providing superior glass solutions. Founded in 2014, our robust infrastructure, including foreign equipment from Germany and Switzerland, enables us to deliver products of exceptional quality. Our products are not only popular in China but also exported to Europe, North America, India, Russia, the Middle East, and other regions.

For more information about our products and services, please visit our homepage. We look forward to serving you.

Remember, when it comes to high-quality UV resistant toughened glass, think Tibbo.