Welcome to this comprehensive guide on the manufacturing process of display cover glass, a critical component in many of our everyday devices. In this guide, we will delve deep into the process, understanding the technologies and expertise involved, and how companies like Tibbo, a renowned glass manufacturer from China, create such high-quality products.

Introduction

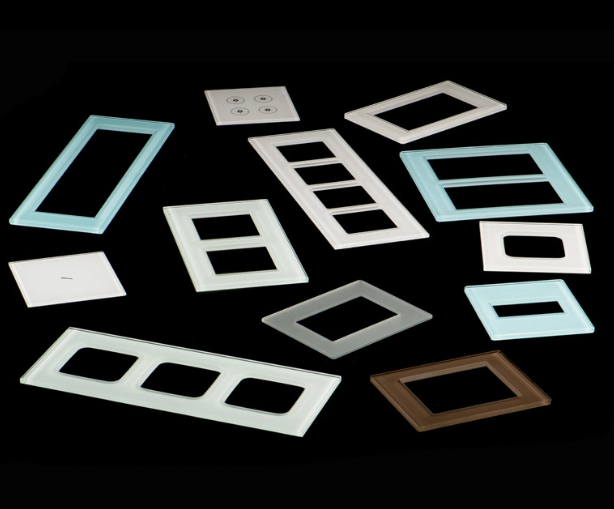

Display cover glass is a significant component in a variety of devices, from smartphones and tablets to televisions and smart home appliances. It serves not only as a protective layer but also enhances the user experience through various features like anti-reflective, anti-glare, and touch-responsive properties.

The Making of Display Cover Glass

Raw Material Preparation

High-quality display cover glass begins with the selection of raw materials. The main ingredient is silica sand (silicon dioxide), followed by small amounts of soda ash (sodium carbonate) to lower the melting point, and limestone (calcium carbonate) to improve durability.

Melting

The raw materials are then placed in a furnace at approximately 1700°C. This extreme heat transforms the materials into a molten state, ready to be formed into glass.

Forming

The molten glass is then poured onto a metal plate where it’s flattened and cooled rapidly. This process, known as tempering, makes the glass stronger and more resistant to damage.

Coating

Next, coatings are applied to enhance the properties of the display cover glass. These may include:

- Anti-Reflective (AR) coating to reduce glare and improve visibility.

- Anti-Fingerprint (AF) coating for a clear, smudge-free display.

- Anti-Glare (AG) coating to decrease light reflection.

Inspection and Quality Control

The final stage involves rigorous testing for quality control. This ensures the glass meets the necessary standards and specifications.

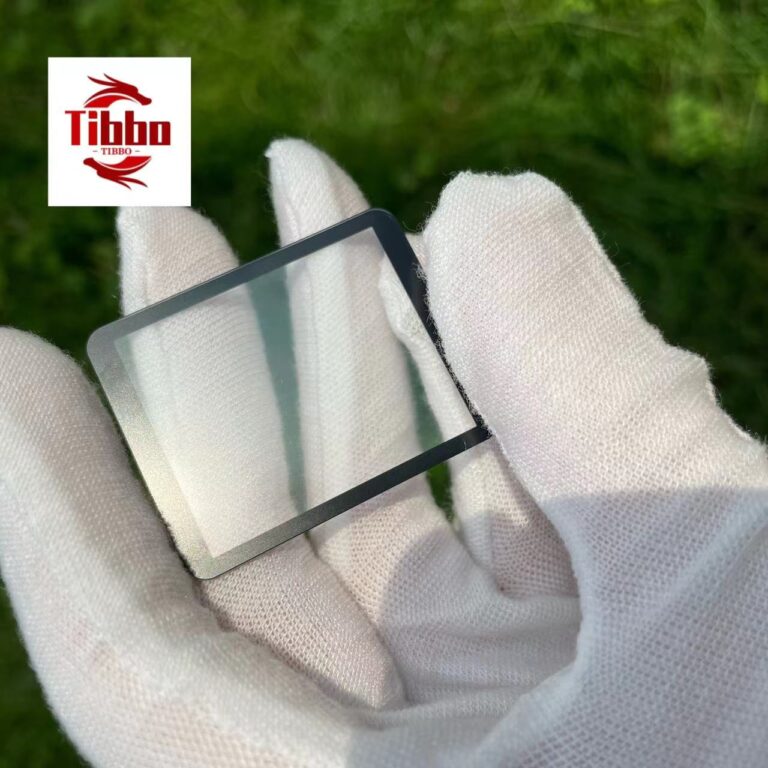

Tibbo: A Leading Manufacturer in China

Tibbo is a top-tier manufacturer of display cover glass in China. Their process involves cutting-edge technology, including high-end testing machines from Germany, high-end CNC machines from Switzerland, and high-precision grinding machine processing equipment. This, combined with a fully automated screen printing coating production line, allows Tibbo to deliver superior quality products consistently.

Their commitment to excellence has led to their products being exported to Europe, North America, India, Russia, the Middle East, and other regions.

Tibbo is also part of the Top 10 Best Display Cover Glass Manufacturers & Suppliers in China. Their B2B offerings are highly sought after, ranging from manufacturing, production, and exporting capabilities.

Conclusion

The process of making display cover glass is complex and requires a high level of expertise and precision. It’s a testament to the manufacturing prowess of companies like Tibbo that we have such high-quality devices at our disposal.

Whether you’re a potential client looking to source display cover glass or just someone interested in the process, we hope this guide has been informative. For further information, head over to Tibbo’s product page where you can explore their extensive range of offerings.

By understanding the process and recognizing the leaders in the field, we can better appreciate the intricate technology that goes into our everyday devices.