Fluorine-doped tin oxide (FTO) coated glass is one of the most critical components in numerous technological applications. From photovoltaic cells to touch screens, this unique material has carved a significant niche for itself in the contemporary tech-driven world. But how is it made? In this comprehensive guide, we delve deep into the world of FTO coated glass, exploring its manufacturing process, applications, and why Tibbo, a leading Chinese manufacturer, is your go-to place for top-quality FTO glass.

What is FTO Coated Glass?

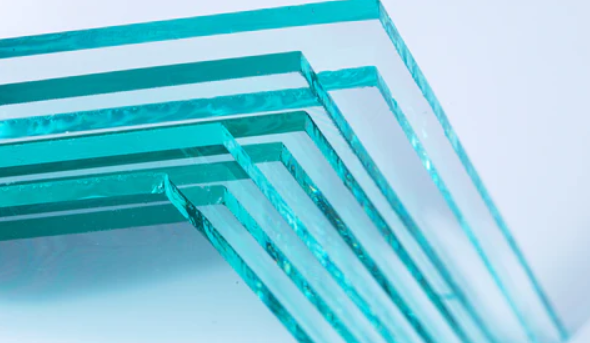

FTO coated glass is a type of glass that has been coated with a thin layer of fluorine-doped tin oxide. This coating imparts excellent electrical conductivity and high transparency to the glass, making it an ideal material for use in a host of applications like solar panels, touch screens, and more.

The Manufacturing Process

The process of making FTO coated glass involves several stages, each of which contributes to the final product’s unique properties. Here is a step-by-step guide on how it’s made:

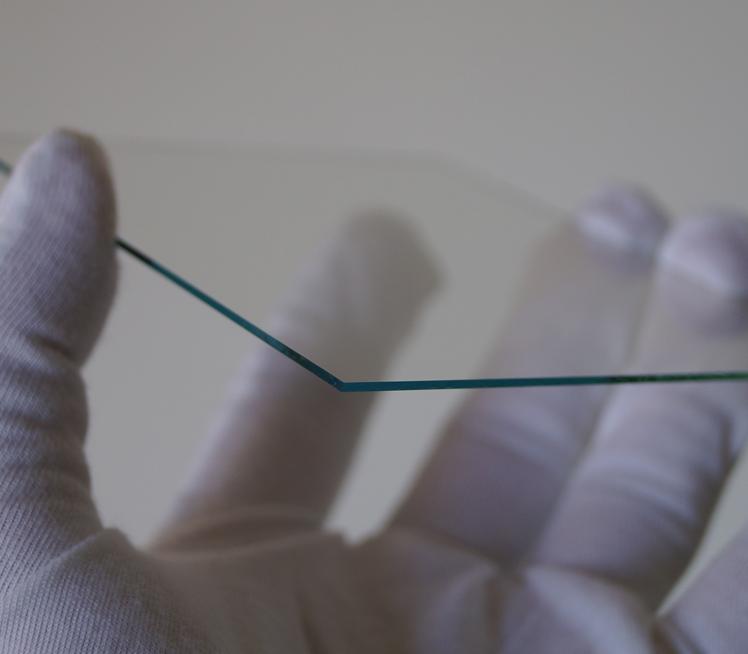

- Glass Selection: The first step involves selecting the right type of glass substrate. This substrate must be clean, smooth, and free from any impurities.

- Deposition Process: The FTO coating is then deposited onto the glass substrate. This is usually done using a technique known as Chemical Vapor Deposition (CVD). During this process, tin and fluorine gases are introduced into a chamber containing the glass substrate. The gases react on the surface of the glass, depositing a thin layer of FTO.

- Annealing: After deposition, the glass is annealed. This process involves heating the glass to a high temperature and then slowly cooling it. Annealing helps to strengthen the FTO coating and improve its electrical conductivity.

- Inspection and Testing: The final step is a thorough inspection and testing of the finished product. This ensures that the FTO coated glass meets the required standards of quality and performance.

Why Choose Tibbo for Your FTO Coated Glass?

Tibbo is a top-tier manufacturer and supplier of FTO coated glass based in China. Established in 2014, Tibbo boasts a robust infrastructure, including a large factory area, state-of-the-art equipment, and a team of highly skilled professionals.

Tibbo’s commitment to quality is backed by multiple certifications, including ISO9001, RoHS, and SGS. Their products are recognized not only in China but are also exported to Europe, North America, India, Russia, the Middle East, and other regions.

When it comes to FTO coated glass, Tibbo ensures superior durability, high light transmittance, and exceptional resistance to environmental conditions. They provide comprehensive glass solutions, with customization options for dimensions, thickness, coating types, and more.

In addition to FTO glass, Tibbo also offers a wide range of other custom glass products, including ITO glass, tempered glass, lighting glass, and more.

Interested in learning more about other coated glass types? Check out our guide on how ITO coated glass is made for more insights.

For inquiries, you can reach out to Tibbo through the contact information provided on their website.

Conclusion

FTO coated glass is a critical material in various technological applications. Knowing how it’s made helps in appreciating the science and engineering behind our everyday devices. And when it comes to sourcing these products, entrust your needs to a reliable manufacturer like Tibbo, a leading authority in the glass manufacturing industry.

Remember, in the B2B landscape, quality, reliability, and trustworthiness are paramount. Choose a partner who guarantees these – choose Tibbo.