In the world of lighting fixtures, the quality of the materials used significantly impacts the final product’s performance, appearance, and longevity. One of the most crucial components is the lighting glass. In this guide, we’ll delve into the intricate process of creating illuminated lighting glass for lamps, a specialty of Tibbo, a leading professional manufacturer and supplier in China.

An Overview of the Illuminated Lighting Glass Manufacturing Process

The process of creating lighting glass involves several carefully controlled steps. These include selecting the raw materials, melting, forming, annealing, and finally, testing.

Raw Material Selection

The creation of quality lighting glass begins with the selection of raw materials. High-grade silica sand, soda ash, and limestone are the primary components. The raw materials are carefully selected to ensure the glass’s clarity, color, and durability.

Melting

The raw materials are heated in a furnace at temperatures reaching 1700°C. This high temperature ensures the melting of the raw materials into a homogeneous molten glass mixture.

Forming

The molten glass is then fed into a forming machine, where it is shaped into the desired form for the lamp. This process can vary depending on the specific requirements of the lamp design.

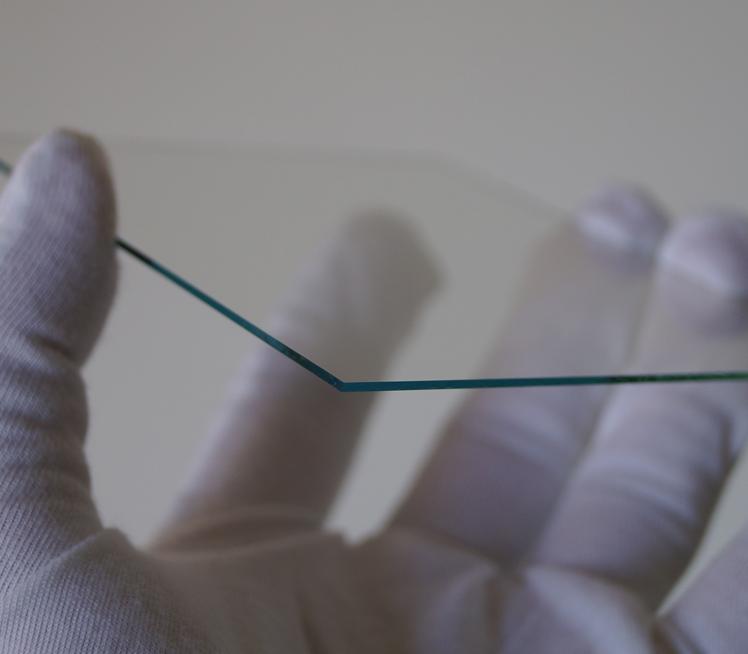

Annealing

The formed glass is then gradually cooled in a process called annealing, which removes stresses within the material and enhances its durability.

Testing

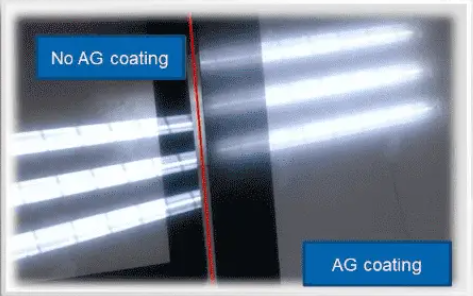

Finally, the finished products undergo rigorous testing to ensure they meet the strict quality standards set by Tibbo. This includes dimensional inspection, strength testing, and visual inspection for defects.

Tibbo: Quality and Expertise in Glass Manufacturing

Tibbo, founded in 2014, has become a trusted name in the B2B sector, both in China and globally. With its robust infrastructure, including a large factory area, high-end German testing machines, Swiss CNC machines, high-precision grinding machine processing equipment, and a fully automated screen printing coating production line, Tibbo is well-equipped to deliver high-quality products.

Tibbo’s commitment to quality doesn’t end at the manufacturing stage. The company also has several high-end laboratory experiment instruments and coating testing equipment to thoroughly inspect the products from all aspects.

The company’s excellent products have gained recognition not only in China but also in export markets such as Europe, North America, India, Russia, and the Middle East.

Why Choose Tibbo?

Tibbo stands out as a professional, high-quality manufacturer and supplier due to its commitment to quality and precision. The company offers a wide range of products, including not just illuminated lighting glass, but also smart home touch panels with chemically tempered glass, among others.

Choosing Tibbo means choosing a partner dedicated to providing superior quality products and exceptional customer service. Trust Tibbo’s expertise in manufacturing, production, and export, and elevate your business to new heights.

Conclusion

Understanding the process of making illuminated lighting glass provides insight into the effort and precision required to create high-quality lighting fixtures. With companies like Tibbo at the forefront of this industry, customers can be assured of the quality and durability of their products. For more information on Tibbo’s range of products, please visit their homepage.

Remember, when it comes to glass products, quality matters, and Tibbo delivers nothing but the best.