Welcome to the comprehensive guide on the manufacturing process of R<1% AR coated glass substrate, brought to you by the authority in glass manufacturing — Tibbo. As a premier B2B manufacturer and supplier based in China, we have been delivering top-notch glass products to the global market since 2014. This guide will shed light on the intricate process of creating this high-quality, specialized glass product.

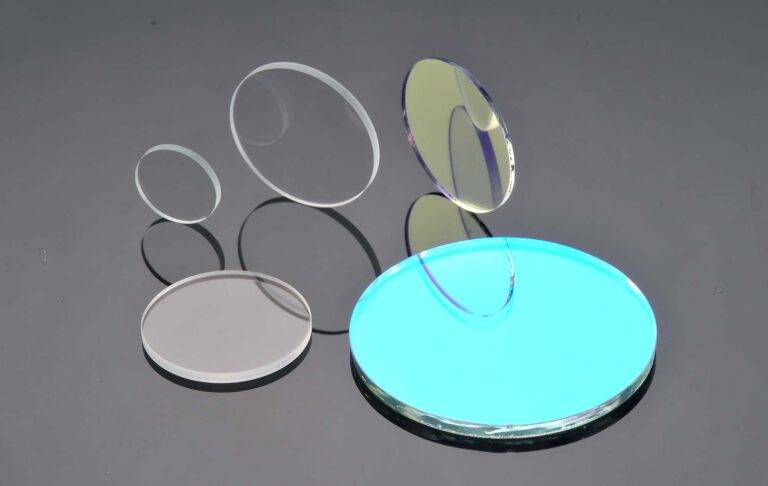

Understanding AR Coated Glass

Anti-reflective (AR) coated glass substrate plays a pivotal role in numerous applications, such as displays, electronic devices, and solar panels. The R<1% AR coating is a testament to the glass’s exceptional anti-reflective properties. But how is this high-performance product made?

The Manufacturing Process

The production of R<1% AR coated glass substrate is a multistep process that requires precision, high-tech machinery, and stringent quality control measures.

1. Glass Selection

The process begins with the selection of high-quality glass substrate. At Tibbo, we use top-grade raw materials to ensure the absolute best end product.

2. Cleaning

The glass is thoroughly cleaned to remove any impurities, as even the smallest particle can impact the coating process.

3. Coating Application

The AR coating is applied using advanced machinery. This coating significantly reduces reflections, offering superior visibility and clarity.

4. Quality Control

Every piece of glass undergoes strict quality control measures. Our state-of-the-art German testing machines and Swiss CNC equipment ensure each product meets the highest standards.

Why Choose Tibbo?

When it comes to manufacturing AR coated glass substrate, Tibbo stands out as a leader in the field. Our robust infrastructure, advanced machinery, and experienced team enable us to produce high-quality products consistently. Our products are not only popular in China but are also exported to Europe, North America, India, Russia, the Middle East, and other regions.

We also offer customization options, catering to a wide range of specific needs. Our comprehensive glass solutions are crafted to meet the unique requirements of each client. For more insights into our manufacturing process, check out our blog post: How is Display Cover Glass Made: The Ultimate Guide.

Conclusion

As a leading manufacturer and supplier, Tibbo is committed to delivering innovative, high-quality glass products. If you’re looking for a reliable partner in the B2B market, look no further. Contact us today to learn how we can meet your glass product needs.

This guide is just the beginning. Dive deeper into the world of glass manufacturing with Tibbo, your trusted partner in quality and innovation.