In the evolving world of technology and innovation, the demand for high-quality, durable glass has never been greater. As one of the leading manufacturers and suppliers in the B2B international export business, Tibbo specializes in producing premium scratch-resistant and UV-resistant glass. This guide delves into the intricate process of how such glass is manufactured.

Understanding Scratch-Resistant and UV-Resistant Glass

Scratch-resistant and UV-resistant glass are two distinct types of specially treated glass. Scratch-resistant glass undergoes a specific process to make its surface more robust and less prone to scratches, while UV-resistant glass is treated to block harmful UV rays. Both types of glass are widely used in various industries, including electronics, automotive, and construction.

The Manufacturing Process

The manufacturing process of this specialized glass involves several sophisticated steps. It begins with the selection of high-quality raw materials, followed by melting, forming, annealing, and finally, the surface treatment that gives the glass its scratch-resistant and UV-resistant properties.

Melting

The first step in producing glass is melting the raw materials. These are typically silica sand, soda ash, and limestone, heated at temperatures of around 1700°C in a furnace.

Forming

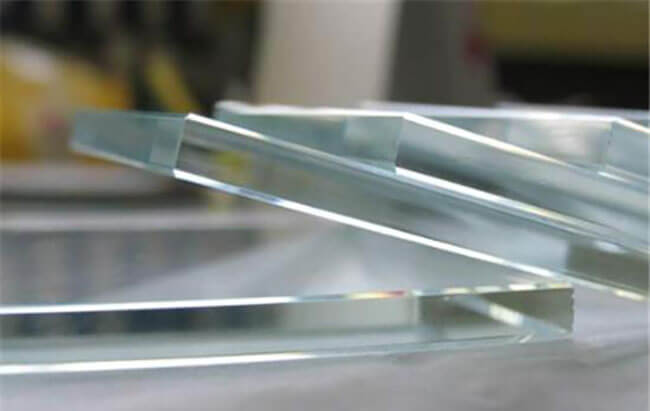

The molten glass is then shaped into the desired form using a procedure called forming. This is typically done by floating the molten glass on a molten metal bed, giving it a smooth, uniform surface.

Annealing

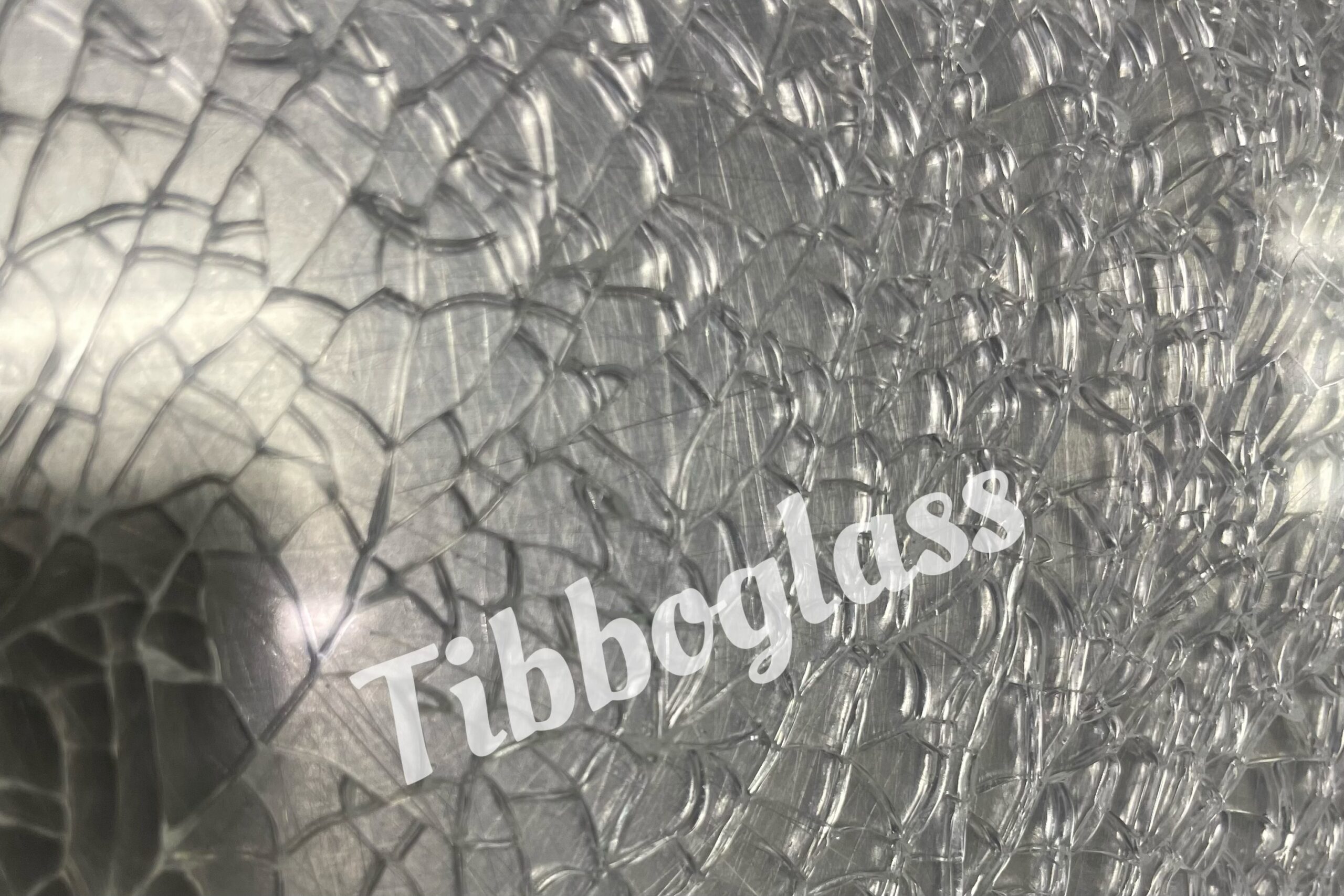

The formed glass is then cooled slowly in a process called annealing. This step removes internal stresses and strengthens the glass.

Surface Treatment

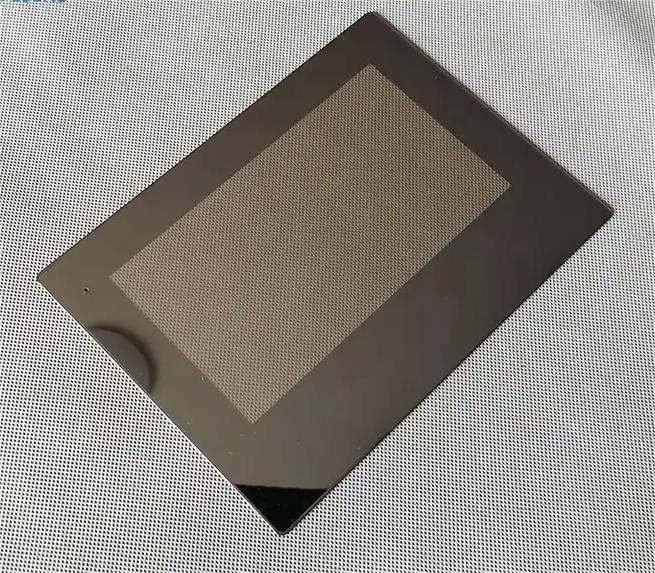

The final step is surface treatment, where the glass is coated with a thin, clear layer of a hard material like diamond-like carbon (DLC) or alumina (Al2O3). This layer makes the glass scratch-resistant.

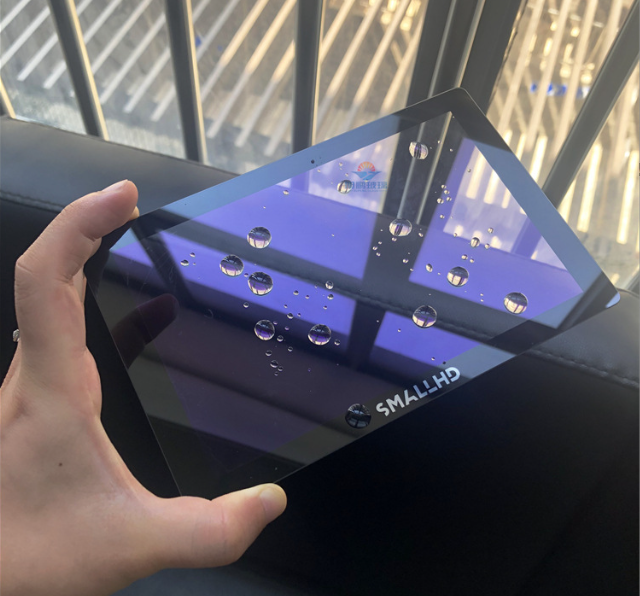

For UV resistance, the glass is coated with a layer of a UV-absorbing material. This coating absorbs harmful UV rays, preventing them from passing through the glass.

Tibbo’s advanced manufacturing process leverages high-end German testing machines, Swiss CNC machines, and high-precision grinding machine processing equipment to ensure a high-quality finish.

Why Choose Tibbo

Established in 2014, Dongguan Tibbo Glass has built a strong reputation as a leading authority in the glass manufacturing industry. With a large factory area equipped with foreign equipment, Tibbo has the strength and capability to produce high-quality products that not only sell well in China but are also exported to Europe, North America, India, Russia, the Middle East, and other regions.

Tibbo’s commitment to quality is evident in its products. The company’s scratch-resistant and UV-resistant glasses are designed to withstand demanding conditions and offer superior performance. They’re a testament to Tibbo’s unwavering dedication to quality and innovation.

For a deeper understanding of the glass manufacturing process, check out our blog post on how ultra-clear glass is made.

As a trusted B2B partner, Tibbo offers customization options for dimensions, thickness, coating types, and more. Each glass solution is designed to meet specific application requirements and ensures superior quality and performance.

Tibbo is not just a manufacturer; it is a trusted partner that provides comprehensive glass solutions. Contact Tibbo today to explore an extensive range of exceptional, high-quality glass products.