In the realm of modern living, smart homes have become a staple. A crucial part of these smart homes is the touch panel with chemical tempered glass. This comprehensive guide, prepared by Tibbo, a top-tier professional manufacturer and supplier in China, will walk you through the manufacturing process of these essential devices.

Introduction

Smart home touch panels serve as the nerve center of an intelligent household, offering a seamless interface for controlling multiple devices and functions. Besides their practicality, these panels also enhance the aesthetic appeal of interiors. The production of these panels involves several meticulous steps that ensure their durability, safety, and functionality.

Manufacturing Process

Design

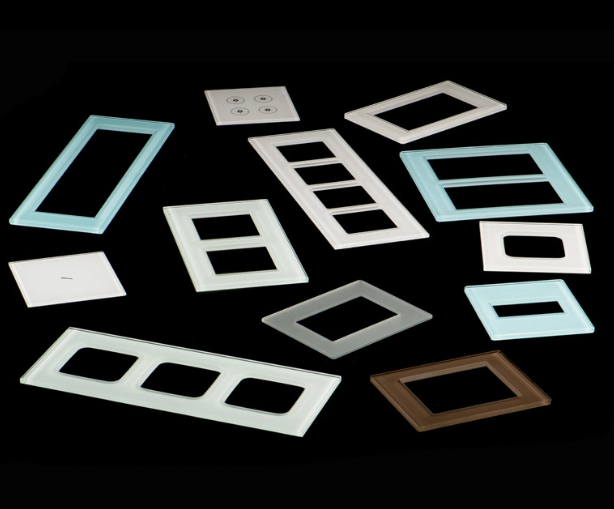

The journey of a smart home touch panel begins with a careful design process. Here, the dimensions, style, and capabilities of the panel are decided. The design must align with safety standards, be user-friendly, and provide a smooth experience for users.

Material Selection

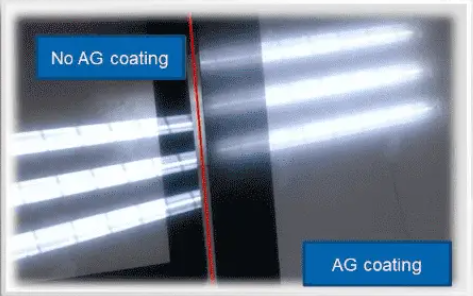

High-quality materials play a significant role in the longevity and reliability of the panels. Plastic is used for the casing, metal for conductive parts, and high-quality glass for the touch panel. The glass undergoes a chemical tempering process to increase its strength and resistance to breakage.

Molding and Assembly

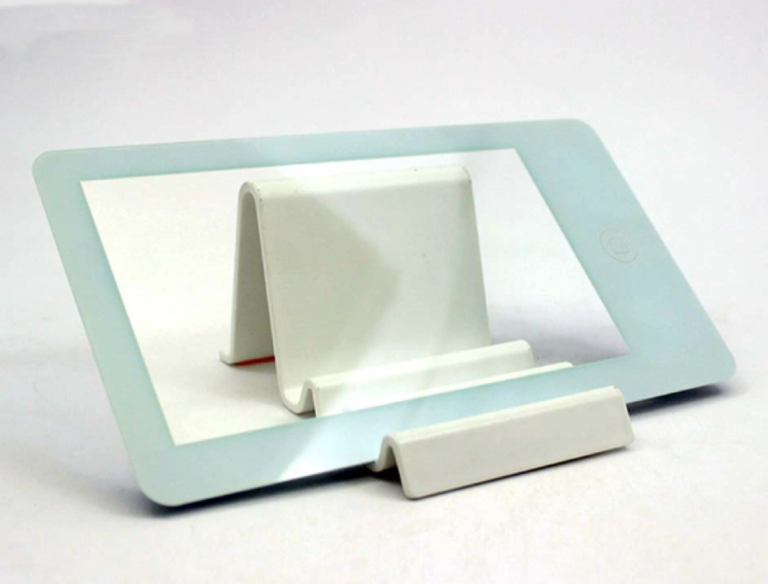

The molding process shapes the plastic and metal parts according to the design. Once these parts are ready, they’re assembled to create the complete smart home touch panel.

Testing

Each assembled touch panel is subjected to rigorous testing to guarantee its safety and functionality. Electrical tests ensure its performance under varying voltage and current conditions, while mechanical tests assess its durability.

Packaging

After passing all tests, the panels are packaged and prepared for distribution. The packaging is designed to protect the panels during transportation and storage.

Tibbo’s Role in the Industry

Tibbo specializes in producing high-quality glass products, including smart home touch panels. Established in 2014, we have steadily grown into a reputable manufacturer and supplier in China. Our facilities are equipped with foreign high-end testing machines, high-precision grinding machine processing equipment, and a fully automated screen printing coating production line, allowing us to consistently deliver exceptional products. Our products are not only popular in China but are also exported to various regions including Europe, North America, India, Russia, and the Middle East.

Conclusion

Understanding the manufacturing process of smart home touch panels is essential for businesses aiming to source high-quality products. With renowned manufacturers like Tibbo, you can rest assured of superior quality and service. For more detailed guides on the manufacturing process of other products, check out our article on How is Switch Socket Panel Made.

In the fast-paced manufacturing industry, partnering with a trusted supplier like Tibbo, known for its commitment to quality and extensive experience in the B2B sector, is a smart choice for businesses seeking reliable manufacturing and export solutions.