Welcome to our comprehensive guide on the manufacturing process of switch socket panels. This guide is specially crafted for businesses in the B2B sector, particularly those interested in manufacturing, production, and export operations. We are Tibbo, a leading professional manufacturer and supplier in China, renowned for our expertise in creating high-quality glass products.

Introduction

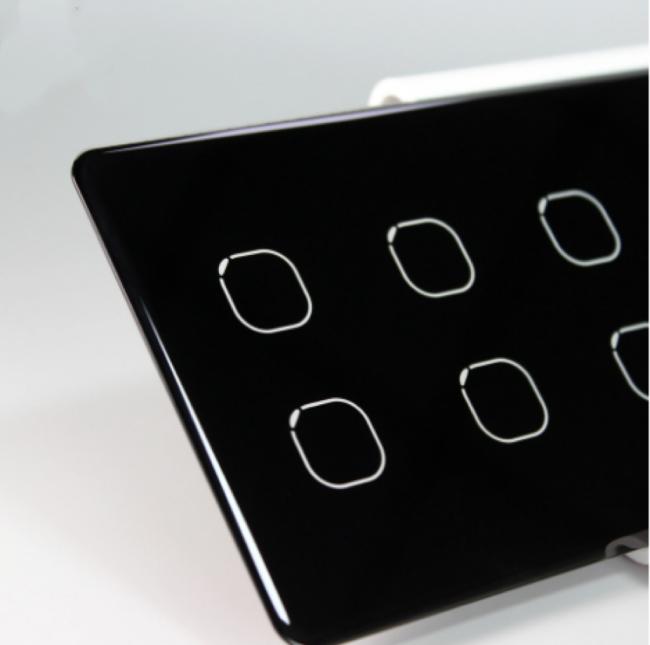

Switch socket panels are an essential component of modern households and offices. Not only do they provide a convenient interface for controlling electrical appliances, but they also contribute to the aesthetic appeal of the interior design. The production process of switch socket panels involves intricate steps and precise execution to ensure the final product’s functionality, safety, and durability.

Manufacturing Process

The manufacturing process of switch socket panels involves several steps, including design, raw material selection, molding, assembly, testing, and packaging. Each stage is vital and requires precise execution to ensure the production of a high-quality and durable switch socket panel.

Design

The process begins with the design phase, where the dimensions, style, and functionality of the switch socket panel are decided. The design must be user-friendly and comply with the safety standards in the industry.

Raw Material Selection

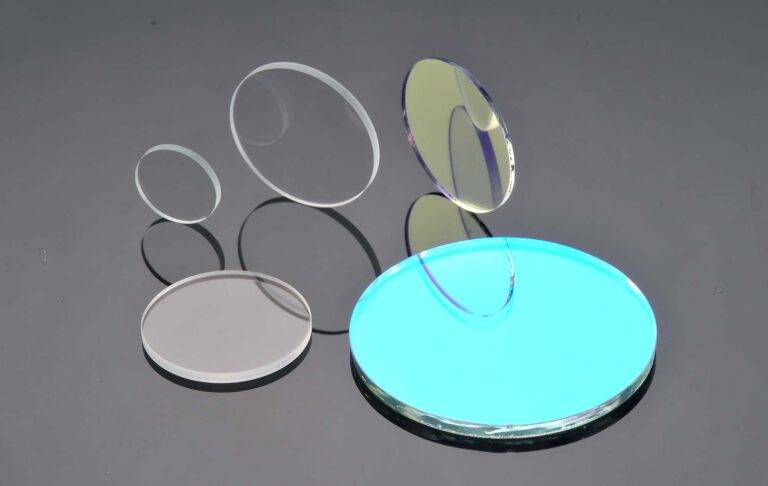

The next step is the selection of raw materials. High-quality materials are essential for the durability and reliability of the switch socket panel. The materials used typically include plastic for the casing, metal for the conductive parts, and high-quality glass for the panel.

Molding and Assembly

After the design and raw material selection, the molding process begins. This involves shaping the plastic and metal parts according to the design. Once the parts are ready, they are assembled to form the complete switch socket panel.

Testing

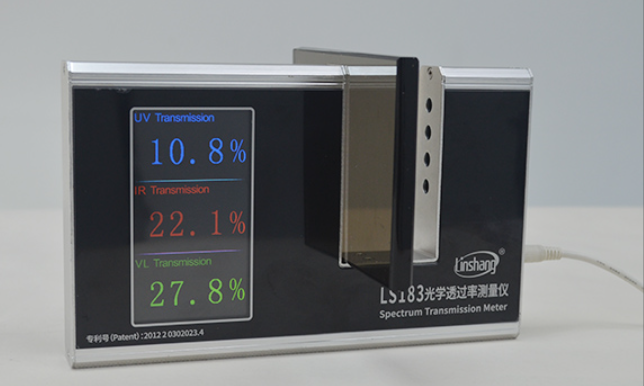

The assembled switch socket panel undergoes stringent testing to ensure its functionality and safety. This includes electrical tests to verify its performance under different voltage and current conditions and mechanical tests to assess its durability.

Packaging

Once the switch socket panels pass all the tests, they are packaged and prepared for distribution. The packaging is designed to protect the product from damage during transportation and storage.

The Role of Tibbo in the Industry

At Tibbo, we specialize in the production of high-quality glass products, including switch socket panels. Incorporated in 2014, we have steadily grown to become a reputable manufacturer and supplier in China. Our state-of-the-art facilities, equipped with German high-end testing machines, Swiss high-end machine CNC, and high-precision grinding machine processing equipment, ensure that we consistently deliver top-notch products. Our products are not only popular in China but also exported to various regions, including Europe, North America, India, Russia, and the Middle East.

Conclusion

Understanding the manufacturing process of switch socket panels is crucial for businesses looking to source high-quality products. With renowned manufacturers like Tibbo, you can be assured of superior quality and service. For more in-depth guides on the manufacturing process of other products, check out our article on How is Heat Resistant Ceramic Glass Made.

In the dynamic world of manufacturing, it’s crucial to partner with a trusted supplier. Tibbo, with its commitment to quality and extensive experience in the B2B sector, stands as an ideal choice for businesses seeking reliable manufacturing and export solutions.