Welcome to a comprehensive exploration of the creation process of the tempered borosilicate glass substrate. In this guide, we will delve into the fascinating world of glass manufacturing, and more specifically, the making of this highly durable and versatile product. Our guide is brought to you by Tibbo, a leading Chinese manufacturer and supplier specializing in various types of glass products for the B2B market.

The Basics of Borosilicate Glass

Borosilicate glass, known for its exceptional thermal resistance, durability, and optical clarity, is a type of glass with silica and boron trioxide as the main glass-forming constituents. It’s widely used in numerous applications, from laboratory glassware to cookware, due to its ability to withstand extreme temperature changes without damage.

The Making of Tempered Borosilicate Glass Substrate

Sourcing the Raw Materials

The first step in the manufacturing process involves sourcing the highest quality raw materials. The primary materials for borosilicate glass include silica sand, boric oxide, soda ash, and alumina.

The Melting Process

The raw materials are carefully weighed and mixed before being transferred to a furnace where they’re heated to a temperature of approximately 1700°C. This extreme heat melts the mixture into a homogeneous liquid.

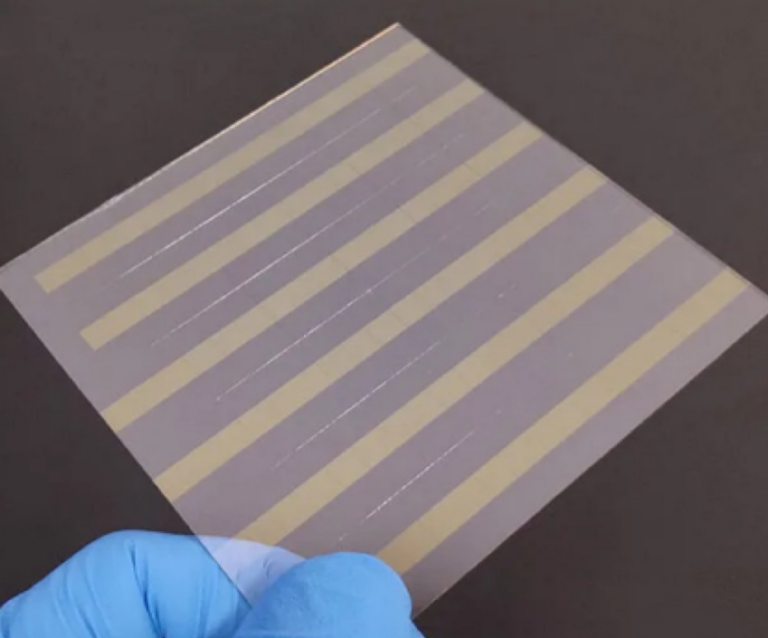

The Forming Process

The molten glass is then poured onto a metal plate, where it spreads out and forms a flat surface. This is referred to as the “sheet glass” process.

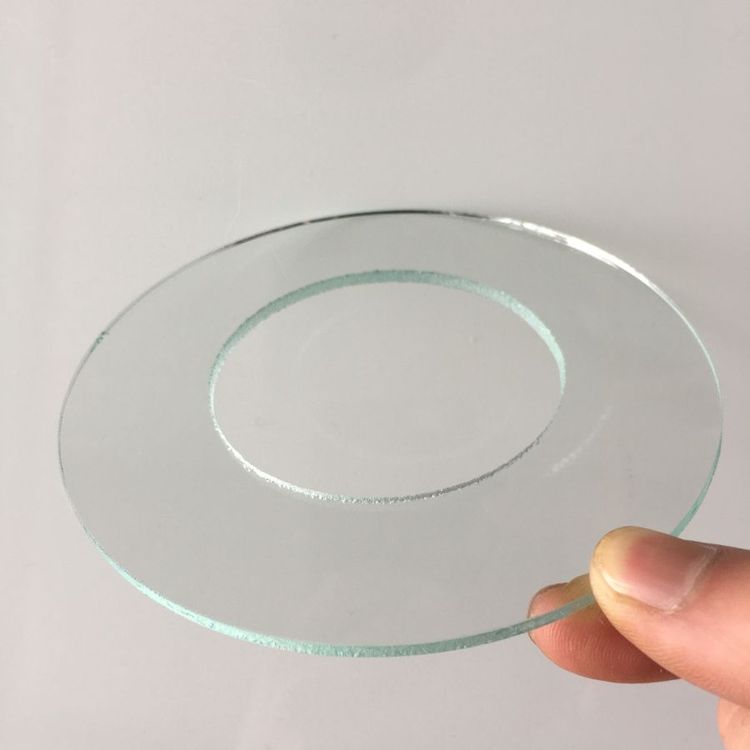

The Tempering Process

The glass sheet is then subjected to a tempering process. It involves heating the glass near its softening point and then rapidly cooling it. This procedure increases the glass’s strength by up to five times compared to untempered glass, making it resistant to breakage and thermal stress.

Quality Control and Assurance

At Tibbo, every piece of glass undergoes rigorous quality checks to ensure that it meets the highest industry standards. Our state-of-the-art testing machines and fully automated production line ensure the consistent quality of our products.

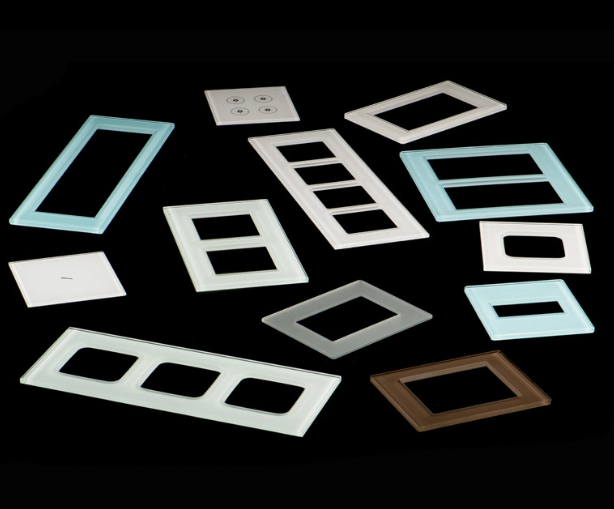

Tibbo: Your Trusted Partner for B2B Glass Solutions

Tibbo, founded in 2014, is a reputable and authoritative Chinese manufacturer and supplier of high-quality glass. Our robust infrastructure includes foreign equipment from Germany and Switzerland, enabling us to deliver exceptional quality products. We not only serve the local Chinese market but also export to Europe, North America, India, Russia, the Middle East, and other regions.

With a strong focus on manufacturing, producing, and exporting, our B2B-oriented business caters to the diverse needs of our clients. We pride ourselves on our ability to provide superior glass solutions, with our tempered borosilicate glass substrate being one of our most popular offerings.

For more insights into the fascinating world of glass manufacturing, check out our previous blog post on how UV resistant toughened glass is made.

When it comes to high-quality tempered borosilicate glass substrates, think Tibbo. We look forward to serving you.