FTO etching glass is crucial in various realization projects, and in many cases, etching it is necessary to enhance its conductivity and efficiency. This article explores the two common FTO glass etching methods: laser etching and chemical etching.

一、laser etching

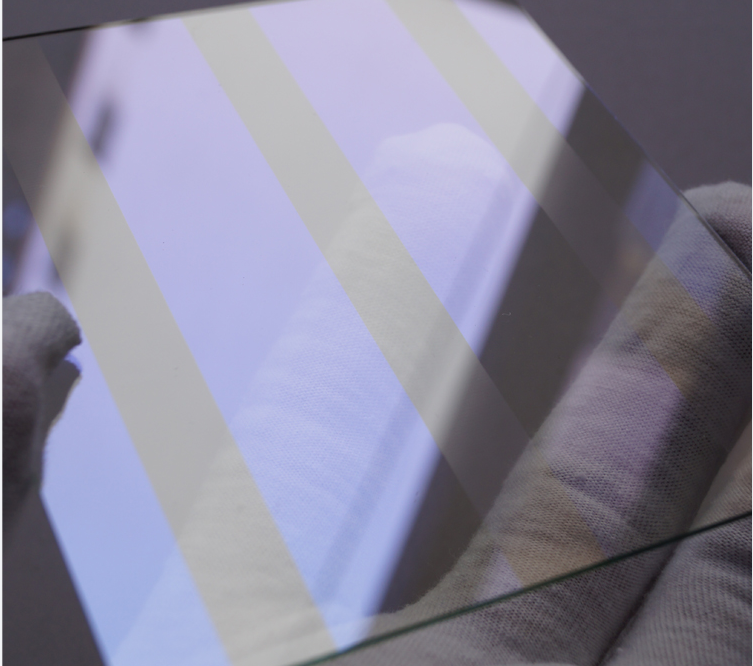

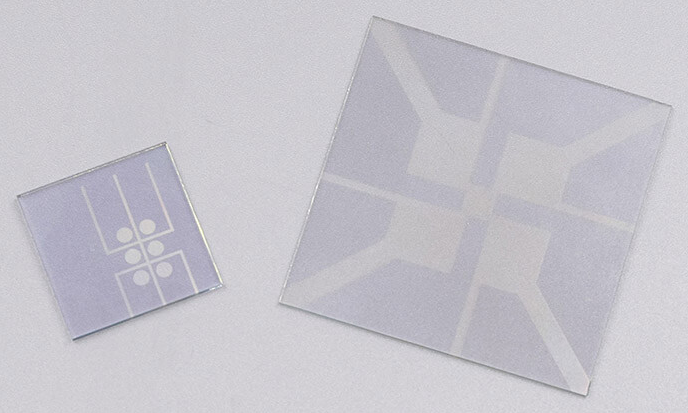

Laser etching involves the precise use of high-energy laser light on the FTO glass surface, causing rapid vaporization of the FTO film (nanosecond level) to create line grooves. This process ensures clean, burr-free, and residue-free grooves while protecting the substrate glass or PET film from damage. It allows for etching on both sides without affecting conductivity. The precision of modern conductive glass laser etching machines can reach as low as 10 microns, making it a widely used method.

二、chemical etching

Chemical etching relies on chemical reagents to corrode the FTO material on the glass substrate. Common materials for this process include hydrochloric acid. Chemical etching is a cost-effective method for FTO glass modification.

三、Advantages and Disadvantages: Laser Etching vs. Chemical Etching

- Cost: Chemical etching is more budget-friendly compared to laser etching.

- Mass Production Efficiency: Chemical etching is more efficient for mass production.

- Environmental Considerations: Laser etching is more environmentally friendly with less waste and higher fidelity.

- Precision: Laser etching offers better control, higher precision, and a higher yield rate, making it suitable for laboratory use.

- Performance: Chemical etching can lead to FTO residue, affecting conductivity.

- Controllability: Laser etching is not limited by graphics and offers more accuracy with narrower lines and smaller spacing.

In summary, whether you prioritize efficiency, performance, or controllability, laser etching stands out as an advantageous method. However, it’s important to note that it comes at a relatively higher cost. In fields like touch screens, photovoltaics, and electrochromic glass, laser etching is widely preferred for etching FTO materials.

Our Tibbo advantages:

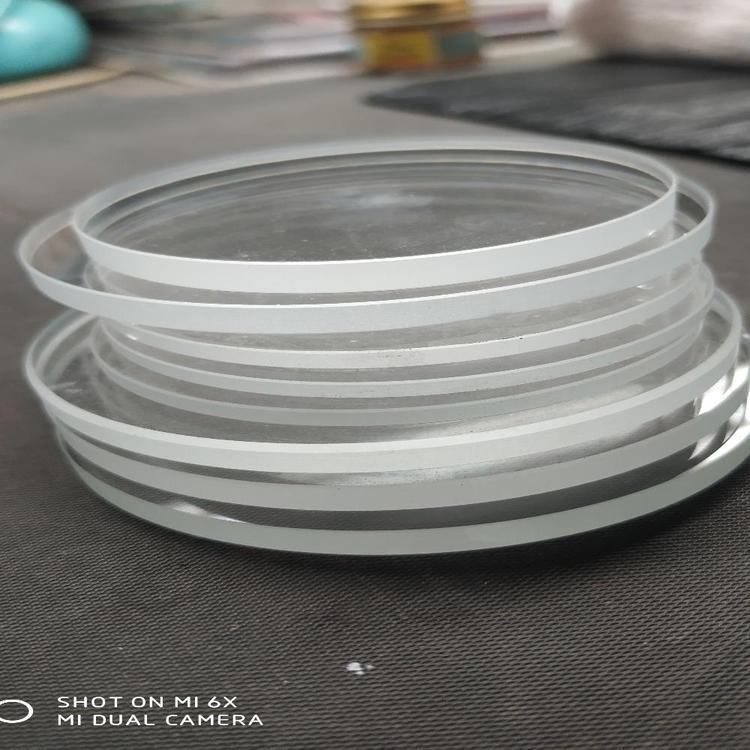

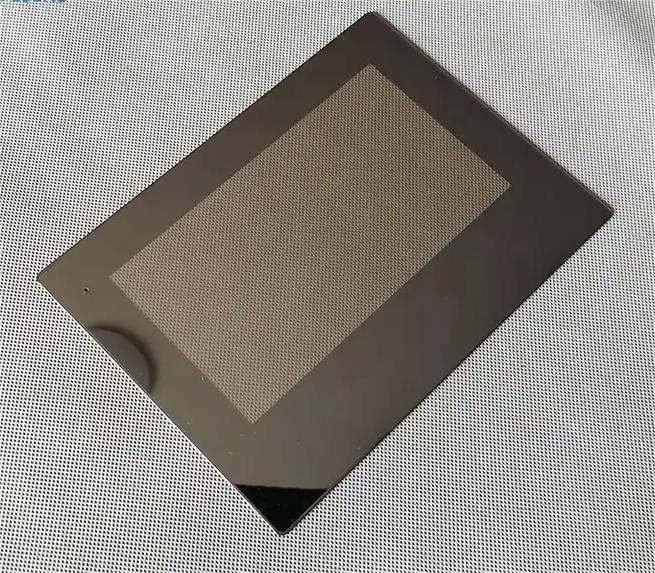

As a leading manufacturer of conductive film glass, our company specializes in ITO/FTO conductive glass, molybdenum-plated glass, float glass, quartz glass, flexible conductive film, and related laboratory equipment.

Our products undergo CNC cutting and laser etching processes, making them ideal for various industries, including solar energy, display, smart home, electronic appliances, optics, university laboratories, and scientific research institutes. We offer custom sizes, thicknesses, and resistance levels, ensuring high-quality products at competitive prices. Contact us today for more information!

Send inquiry to us : https://tibboglass.com/contact-us/

Tibbo Instragm : https://instagram.com/tibboglass?igshid=OGQ5ZDc2ODk2ZA==

Tibbo Facebook: https://www.facebook.com/profile.phpid=61550780595281&mibextid=LQQJ4d