When it comes to cutting-edge materials for electronics and optoelectronics, ITO Coated Glass Substrate from Tibbo stands out for its impeccable quality and innovation. Dongguan Tibbo Glass, since its inception in 2014, has been a paragon of excellence in manufacturing ITO coated glass substrates, leveraging advanced technology and a commitment to quality.

Introduction to ITO Coated Glass Substrates

The Critical Role of ITO Coated Substrates

Understanding ITO Coatings

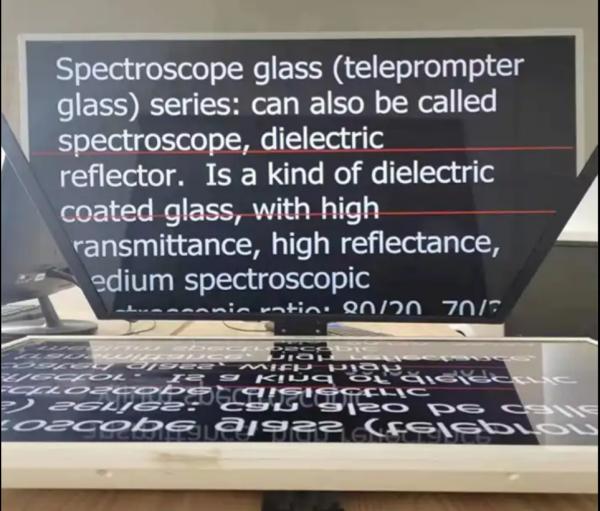

Indium Tin Oxide (ITO) coatings are known for their transparent conductive properties, which make them indispensable in the production of various electronic devices such as touchscreens, LCDs, and solar panels. The ITO Coated Glass Substrate from Tibbo is a testament to the company’s dedication to quality and performance.

The Manufacturing Prowess of Tibbo

State-of-the-Art Facilities and Equipment

Harnessing Advanced Technology

Dongguan Tibbo Glass prides itself on its state-of-the-art facilities and the integration of foreign equipment. With German high-end testing machines, Swiss CNCs, and high-precision grinding machines, Tibbo ensures that every ITO coated glass substrate meets the highest standards.

Automation and Precision

Consistency Across Production

The fully automated screen printing coating production line at Tibbo not only enhances the efficiency of the production process but also ensures that every substrate is consistent in quality, a key aspect for clients who demand reliability in high-volume orders.

The Global Impact of Tibbo’s ITO Coated Glass Substrates

Beyond China: A World-Class Supplier

Meeting the Demands of a Global Market

It’s not just the domestic market that Tibbo caters to; the company’s ITO coated glass substrates are sought after globally. With exports to Europe, North America, India, Russia, the Middle East, and more, Tibbo has established itself as a global leader.

Quality Assurance and Certification

Adherence to International Standards

Tibbo’s commitment to quality extends to meeting international standards, ensuring that their products are not only compliant but also competitive on a global scale.

The Advantages of Choosing Tibbo

Customization and Client-Centric Approach

Tailored Solutions for Diverse Needs

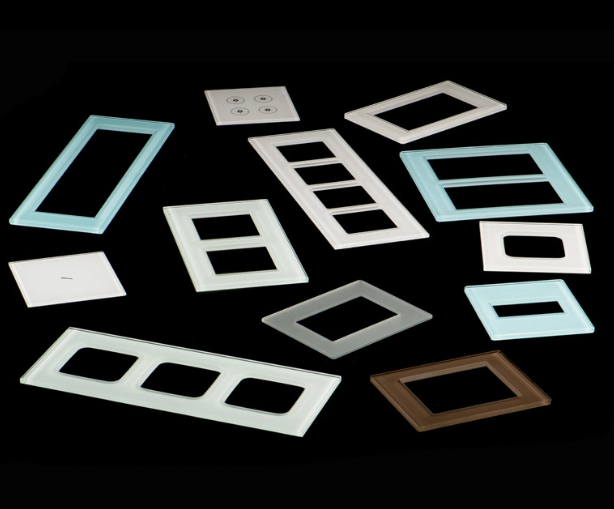

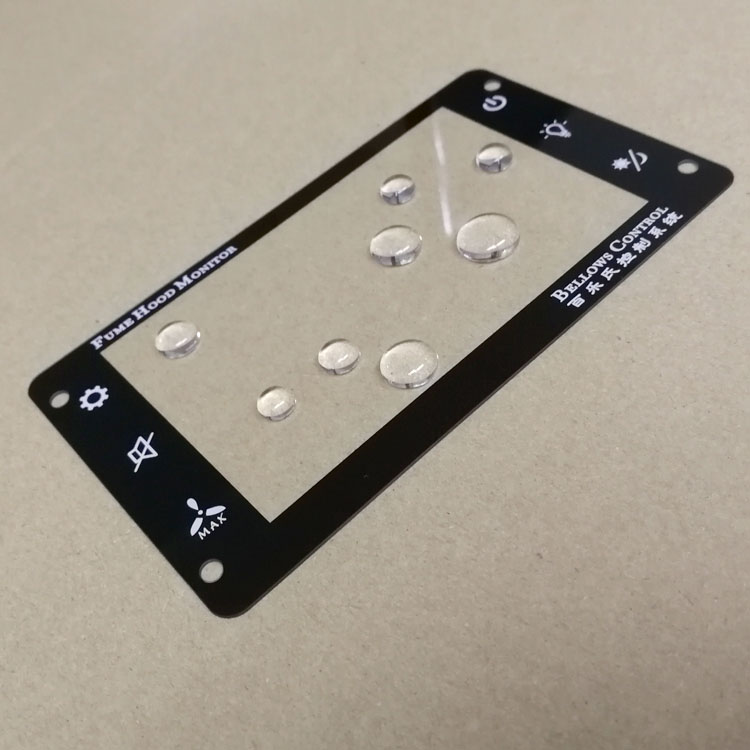

Understanding that different clients have unique requirements, Tibbo offers customized ITO coated glass substrates to meet various specifications. Their client-centric approach is evident in their flexible production capabilities and responsive customer service.

A Future-Focused Company

Innovation at the Core

With a keen eye on the evolving market trends and technological advancements, Tibbo is dedicated to continuous improvement and innovation, ensuring that they remain at the forefront of the ITO coated glass substrate industry.

Frequently Asked Questions About Tibbo’s ITO Coated Glass Substrates

What sets Tibbo’s ITO coated glass substrates apart from competitors?

Tibbo’s substrates stand out due to their superior quality, adherence to international standards, advanced manufacturing processes, and customized solutions.

Can Tibbo handle specialized orders for ITO coated glass substrates?

Yes, Tibbo’s production facilities and technology allow for specialized orders to be fulfilled with precision and efficiency.

What industries benefit from Tibbo’s ITO coated glass substrates?

Industries such as consumer electronics, automotive, renewable energy, and optoelectronics benefit greatly from Tibbo’s ITO coated glass substrates.

Conclusion

The journey to finding the best ITO Coated Glass Substrate leads to Tibbo, a company that not only understands the intricacies of the product but also the complexities of the market. For a deeper dive into Tibbo’s offerings, visit the homepage, explore their product category, or gain further insights on their blog.