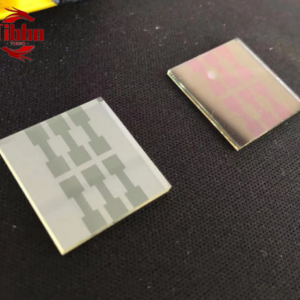

10 ohm sheet resistance ITO glass

ITO glass

tempered glass

conductivity and transparency,

Used in ouchscreen devices, LCDs, solar panels, electronic devices, and lighting.

More detail customized

FTO conductive glass and ITO conductive glass seems to be a pair of twins, the name is only a difference of one character, but also are a kind of conductive glass. So, you may ask: what is the difference and connection between FTO glass and ITO glass, can they replace each other?

ITO Glass

1, definition-wise, the two have different coating layer compositions.

ITO conductive glass refers to the sodium-calcium-based or silicon-boron based substrate glass on the basis of the use of magnetron sputtering method coated with a layer of indium tin oxide film processed glass. FTO conductive glass refers to fluorine-doped tin dioxide conductive glass.

2, conductive properties, ITO glass conductivity is better than FTO glass, FTO glass if not specially treated, its laminated surface barrier is high, not easy to transmit electrons.

FTO Glass

3, cost cost, FTO glass cost is lower than ITO glass;

4, in terms of etching difficulty, the etching process of FTO glass is easier than that of ITO glass;

5, high temperature resistance, FTO glass is better than ITO high temperature resistance, the former can be up to 700 degrees;

6, FTO glass sintering after the square resistance change is relatively small, than with ITO glass to do the printing electrode when the sintering effect is good;

7, transmittance, FTO glass square resistance value is large, low transmittance rate, ITO glass transmittance rate is higher.

ITO glass

tempered glass

conductivity and transparency,

Used in ouchscreen devices, LCDs, solar panels, electronic devices, and lighting.

More detail customized

ITO glass

tempered glass

conductivity and transparency,

Used in ouchscreen devices, LCDs, solar panels, electronic devices, and lighting.

More detail customized

8ohms ITO Glass

Photovoltaic Glass

50*50*1.1mm ITO Conductive Glass

Glass for Lab testing

High elective conductive & Low resistant

ITO glass

tempered glass

conductivity and transparency,

Used in ouchscreen devices, LCDs, solar panels, electronic devices, and lighting.

More detail customized

Some key points about ITO Conductive Glass (Indium Tin Oxide Conductive Glass) and its applications: **Features of ITO Conductive Glass:** 1. **Conductivity:** ITO Conductive Glass possesses high electrical conductivity, allowing it to conduct electrical current, making it suitable for use in electronic devices and displays. 2. **Transparency:** Despite its conductivity, ITO Conductive Glass maintains high…

ITO glass

tempered glass

conductivity and transparency,

Used in ouchscreen devices, LCDs, solar panels, electronic devices, and lighting.

More detail customized

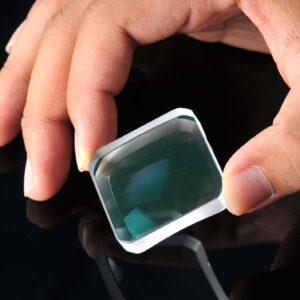

Optical glass

High Transparency&Low Dispersion

Optical Coatings

High-Temperature Stability

Low Color Shift

Optical glass

High Transparency&Low Dispersion

Optical Coatings

High-Temperature Stability

Low Color Shift

Chemical strengthen

Ultra clear glass

High transmittance

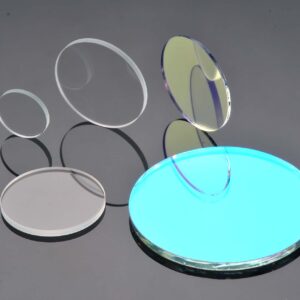

Without printing

Round shape

Diameter &thickness can be customized

Tinted coated glass

Vibrant Colors (blue, green, gray, bronze , etc., customized)

UV Filtering

Weather Resistance

Energy Efficiency

Privacy Protection

Weather Resistance

Tinted coated glass

Color tinted coating

UV Filtering

Weather Resistance

Energy Efficiency

Privacy Protection

Weather Resistance