In the world of modern technology, innovation is the driving force behind the ever-expanding horizons of our devices and gadgets. One such innovation that has played a crucial role in the development of touchscreens, displays, and more is Indium Tin Oxide (ITO) glass. In this blog, we’ll dive into the fascinating world of ITO glass, exploring what it is, how it works, and its wide-ranging applications.

What is ITO Glass?

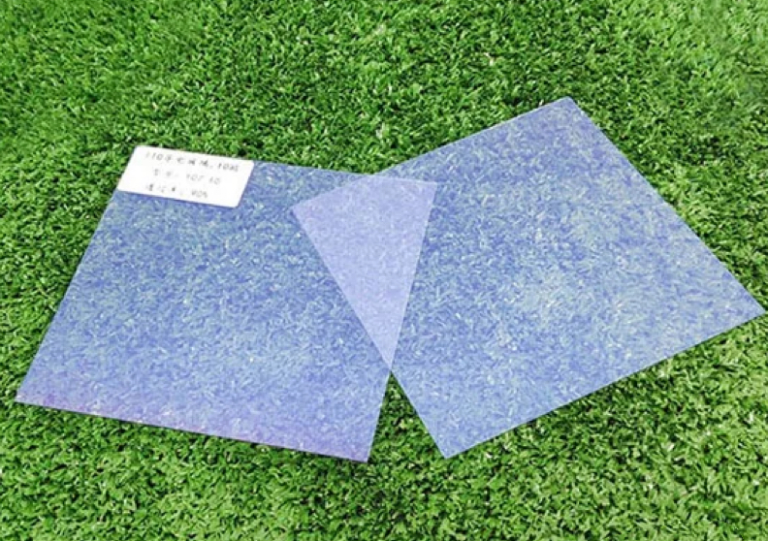

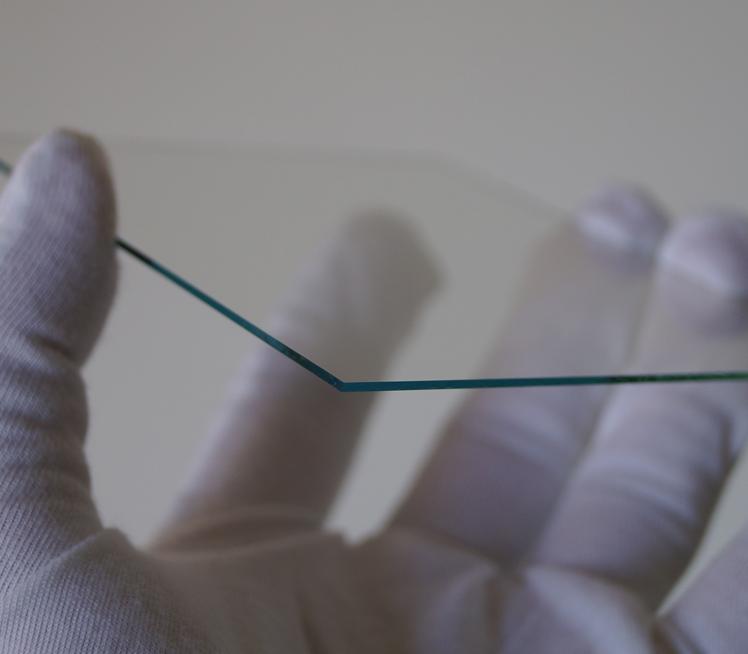

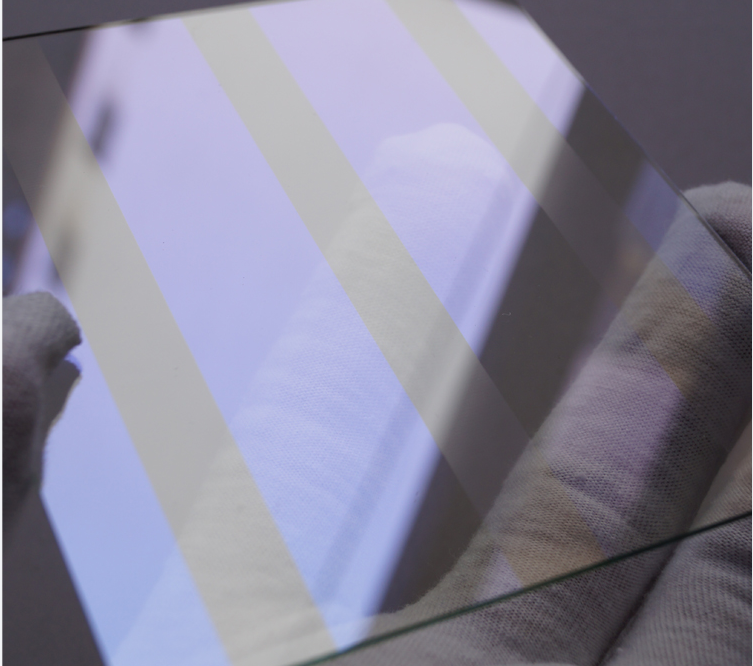

Indium Tin Oxide (ITO) is a transparent and conductive material made from a combination of indium, tin, and oxygen. When this material is applied as a thin layer to glass or other transparent substrates, it forms what we commonly refer to as ITO glass. This transparent conductive coating is essential for various electronic and optoelectronic applications.

How Does ITO Glass Work?

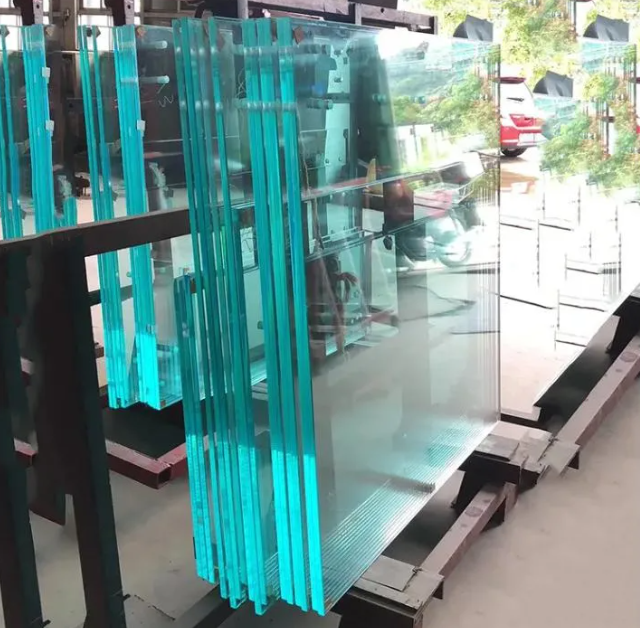

The magic of ITO glass lies in its unique combination of properties. It is transparent, allowing light to pass through, while also being electrically conductive. This makes it ideal for applications where both transparency and conductivity are required.

- Conductivity: ITO glass is made up of indium tin oxide nanoparticles that create a network of conductive paths. These paths allow electrical current to flow through the glass while maintaining its transparency.

- Transparency: ITO’s high transmittance in the visible spectrum makes it an excellent choice for touchscreens and displays. It allows for the passage of light, making screens vibrant and easy to read.

Applications of ITO Glass

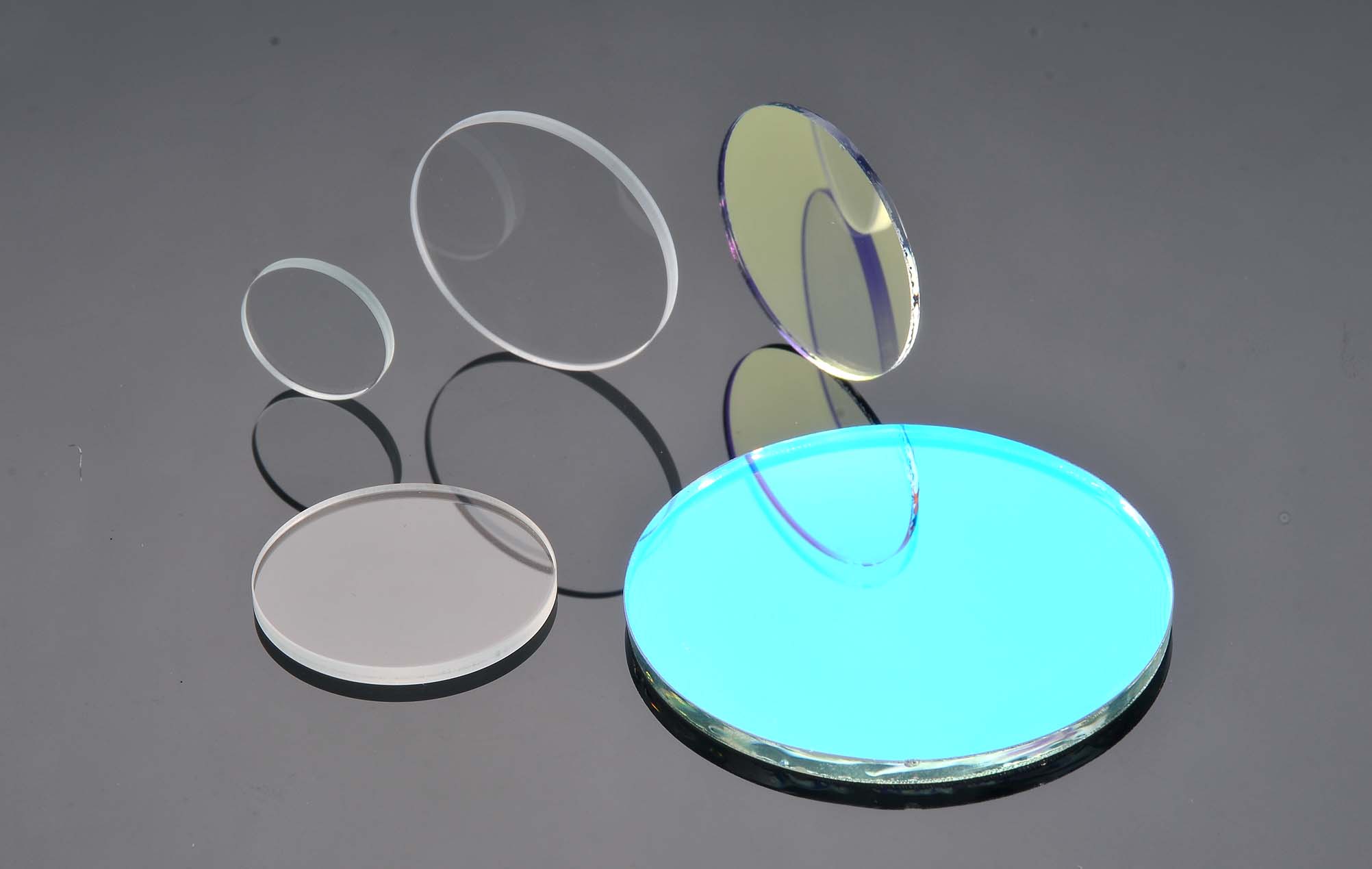

- Touchscreens: Perhaps the most well-known use of ITO glass is in touchscreens for smartphones, tablets, and other electronic devices. The transparent conductive coating allows users to interact with their devices through touch gestures.

- LCD Displays: Liquid Crystal Displays (LCDs) commonly use ITO glass for their electrodes. It enables precise control of individual pixels to produce images and text on screens.

- OLED Displays: Organic Light Emitting Diode (OLED) displays benefit from ITO glass due to its conductivity and transparency. OLED technology is used in many high-end TVs and smartphones.

- Solar Panels: ITO coatings are used in some types of solar panels to improve their efficiency and performance. The transparency of ITO glass allows sunlight to pass through to the photovoltaic cells.

- EMI Shielding: In electronics, ITO glass can also be used for electromagnetic interference (EMI) shielding. It helps protect sensitive components from external interference while maintaining visibility.

Challenges and Future Developments

While ITO glass has been a game-changer in the electronics industry, it’s not without its challenges. One major issue is the scarcity of indium, a primary component of ITO. Researchers are actively exploring alternative materials and coatings to address this concern.

Moreover, as technology continues to advance, there is a growing demand for even more transparent and flexible conductive materials. This has led to the development of alternatives like graphene and silver nanowires, which could potentially replace ITO in certain applications.

Conclusion

Indium Tin Oxide (ITO) glass has left an indelible mark on modern technology, enabling the creation of sleek and interactive devices that we often take for granted. Its unique combination of transparency and conductivity has paved the way for advancements in touchscreen technology, displays, solar panels, and more. While challenges like indium scarcity exist, ongoing research ensures that the world of transparent conductive materials continues to evolve. As we move forward, we can expect even more innovations that push the boundaries of what’s possible in the world of electronics and optoelectronics.

Send inquiry to us : https://tibboglass.com/contact-us/

Tibbo Instragm : https://instagram.com/tibboglass?igshid=OGQ5ZDc2ODk2ZA==

Tibbo Facebook: https://www.facebook.com/profile.phpid=61550780595281&mibextid=LQQJ4d