Here’s a blog post about ITO Glass .Understanding ITO glass Applications, Characteristics, and Future Developments

Introduction

ITO Glass, short for Indium Tin Oxide Glass, is a critical material in the modern tech landscape. Its unique properties make it indispensable in various electronic devices and display technologies. In this article, we will delve into the applications, characteristics, and future trends of ITO Glass to provide you with a comprehensive understanding of this crucial material.

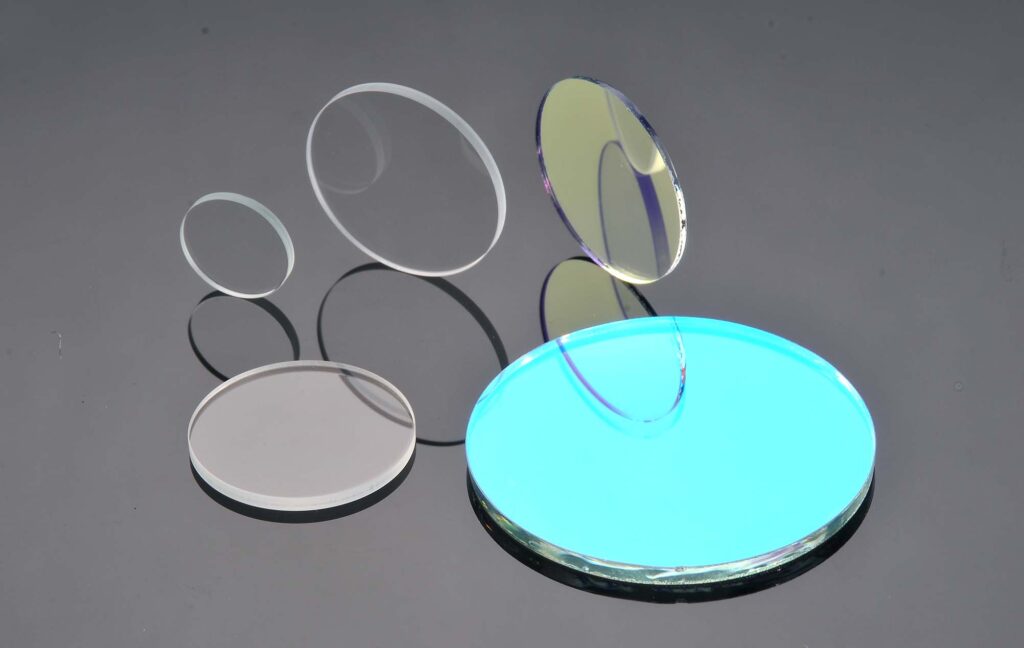

1. An Overview of ITO Glass

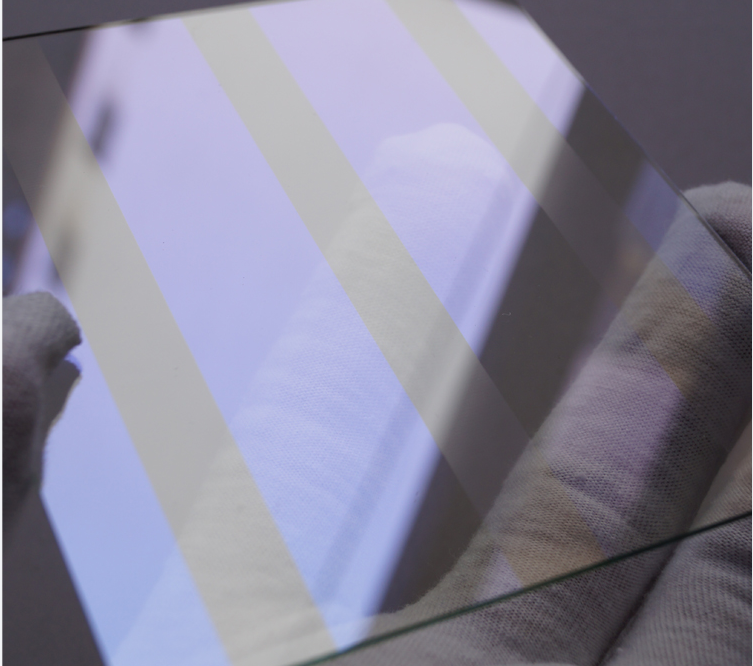

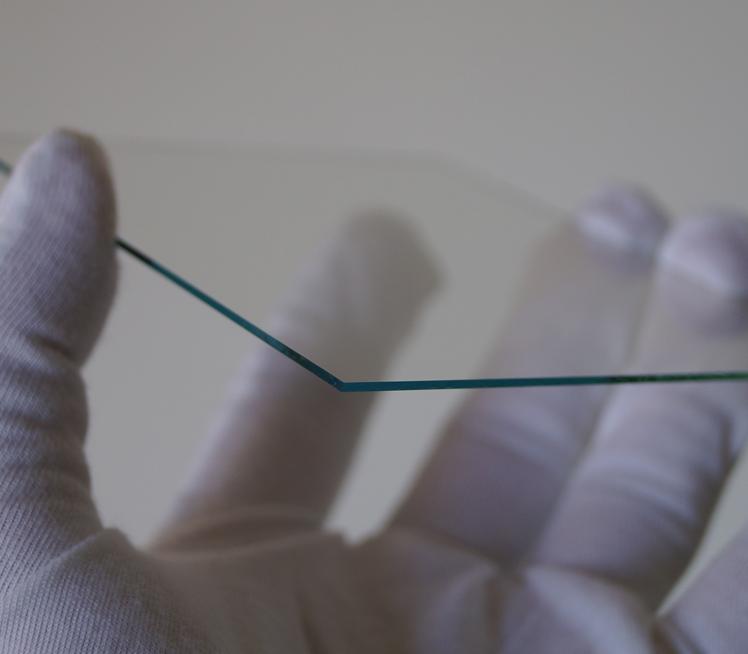

ITO Glass is a transparent conductive material composed of indium oxide and tin oxide. It boasts high transparency and excellent electrical conductivity, making it an essential component in many modern electronic devices. ITO Glass can be manufactured as thin films, applied to glass surfaces, providing conductivity while preserving high transparency.

2. Applications of ITO Glass

ITO Glass finds widespread applications across various fields, including but not limited to:

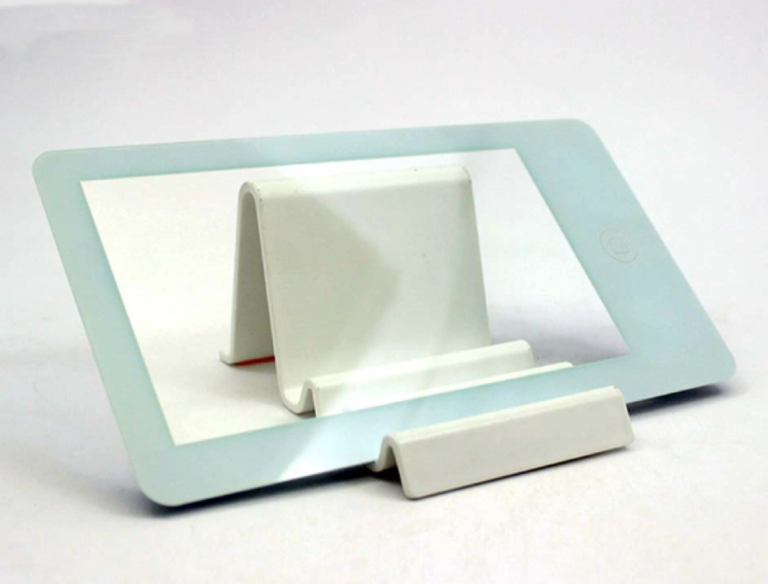

- 2.1 Flat Panel Displays and Touchscreens: ITO Glass is a key component in LCD displays and touchscreens, ensuring clear image quality while allowing for touch interactions.

- 2.2 Solar Panels: ITO Glass is used as a cover material for solar panels, efficiently capturing solar energy and converting it into electricity.

- 2.3 Smartphones and Tablets: The touchscreen of your smartphone or tablet likely incorporates ITO Glass, enabling responsive touch controls.

- 2.4 LCD TVs: ITO Glass plays a crucial role in LCD TV panels, ensuring the transmission and display of high-definition images.

3. Characteristics of ITO Glass

ITO Glass is favored for its unique characteristics, including:

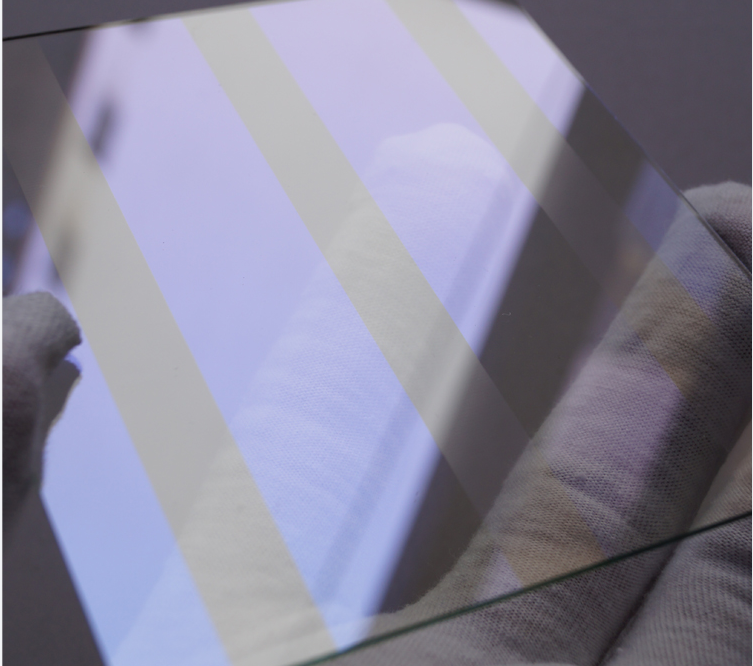

- 3.1 High Transparency: ITO Glass allows the passage of most visible light, making it an ideal choice for various display technologies.

- 3.2 Excellent Electrical Conductivity: ITO Glass exhibits outstanding electrical conductivity, facilitating current flow and the functionality of electronic devices.

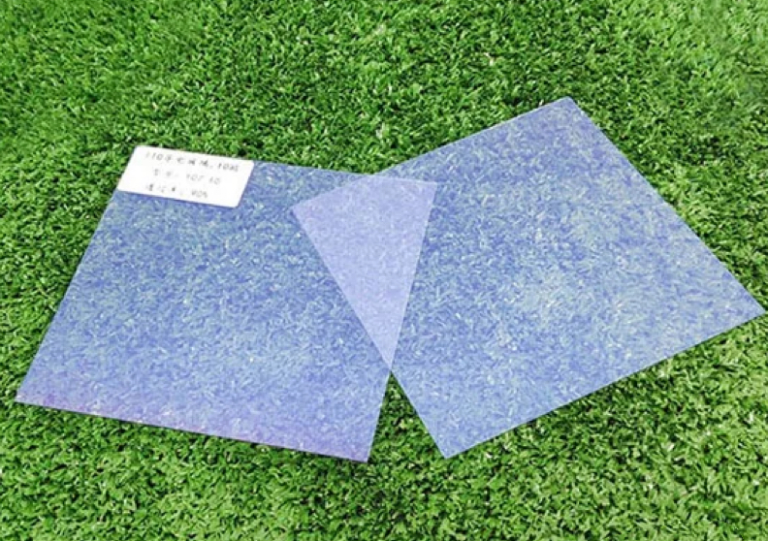

- 3.3 Thin-Film Fabrication: ITO thin films can be easily prepared on various substrates, including glass and plastic.

- 3.4 Corrosion Resistance: ITO Glass is resistant to most chemicals, maintaining stable performance in diverse environments.

4. Future Trends

As electronic technology advances, ITO Glass faces challenges such as cost and resource scarcity. Hence, scientists and engineers are continually exploring alternative materials and technologies to meet the demands of future electronic devices. Some promising alternatives include zinc oxide films, carbon nanotubes, and flexible organic electronic materials. These emerging technologies hold the potential to revolutionize electronic device manufacturing in the future.

Conclusion:

As electronic technology advances, ITO Glass faces challenges such as cost and resource scarcity. Hence, scientists and engineers are continually exploring alternative materials and technologies to meet the demands of future electronic devices. Some promising alternatives include zinc oxide films, carbon nanotubes, and flexible organic electronic materials. These emerging technologies hold the potential to revolutionize electronic device manufacturing in the future.

ITO Glass stands as a critical material in modern electronic devices and display technologies, thanks to its high transparency and conductivity. However, as technology evolves, we anticipate witnessing more innovations in materials and methods to address future challenges and drive progress in the electronics field.

We hope this blog post helps you gain a better understanding of ITO Glass and its significance in contemporary technology. If you have any further questions or seek more related information, please don’t hesitate to contact us.

Send inquiry to us : https://tibboglass.com/contact-us/

Tibbo Instragm : https://instagram.com/tibboglass?igshid=OGQ5ZDc2ODk2ZA==

Tibbo Facebook: https://www.facebook.com/profile.phpid=61550780595281&mibextid=LQQJ4d