In our fast-paced and technology-driven world, the demand for high-quality, durable, and versatile materials is constantly growing. Among these materials, one that has been gaining significant attention in various industries is tempered aluminosilicate glass substrate. So, what exactly is a tempered aluminosilicate glass substrate? How does it function in different applications? This guide aims to answer these questions and more.

In this guide, you will find a comprehensive introduction to tempered aluminosilicate glass substrate, including:

- What tempered aluminosilicate glass substrate is and why it’s vital in today’s industries.

- The different types of tempered aluminosilicate glass substrate and how they function.

- Tips, tools, and best practices to excel in the field of tempered aluminosilicate glass substrate.

Read on to explore the world of tempered aluminosilicate glass substrates, a world of innovation and evolution.

What is Tempered Aluminosilicate Glass Substrate?

Tempered aluminosilicate glass substrate is a type of specially formulated glass that has been strengthened through a process of tempering. This glass substrate has superior thermal stability, chemical resistance, and mechanical strength, making it ideal for various applications in different industries, including electronics, automotive, and more.

Why is Tempered Aluminosilicate Glass Substrate Important?

The benefits of tempered aluminosilicate glass substrate are manifold.

- Durability: The tempering process makes this type of glass extremely resistant to physical impact and thermal shock.

- Versatility: Its properties make it suitable for a wide range of applications, from electronics and automotive to solar panels and other high-tech applications.

- Performance: Compared to other types of glass, tempered aluminosilicate glass substrate offers superior optical clarity and light transmission, crucial in many high-tech applications.

Types of Tempered Aluminosilicate Glass Substrate

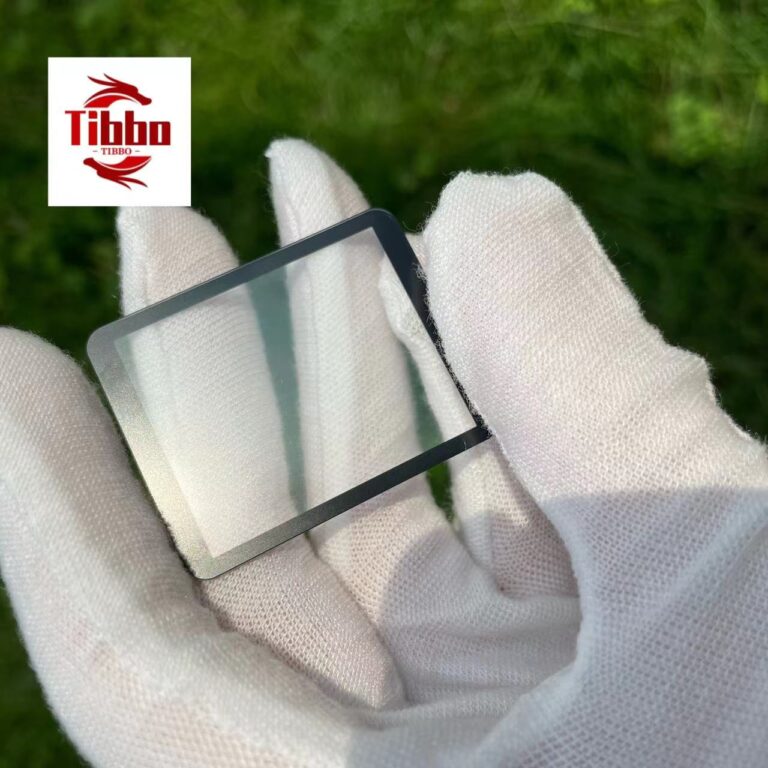

Tempered aluminosilicate glass substrates can be categorized based on their thickness, coating type, and application fields. For instance, at Tibbo Glass, we offer a variety of tempered aluminosilicate glass substrates, each designed to meet specific industry needs.

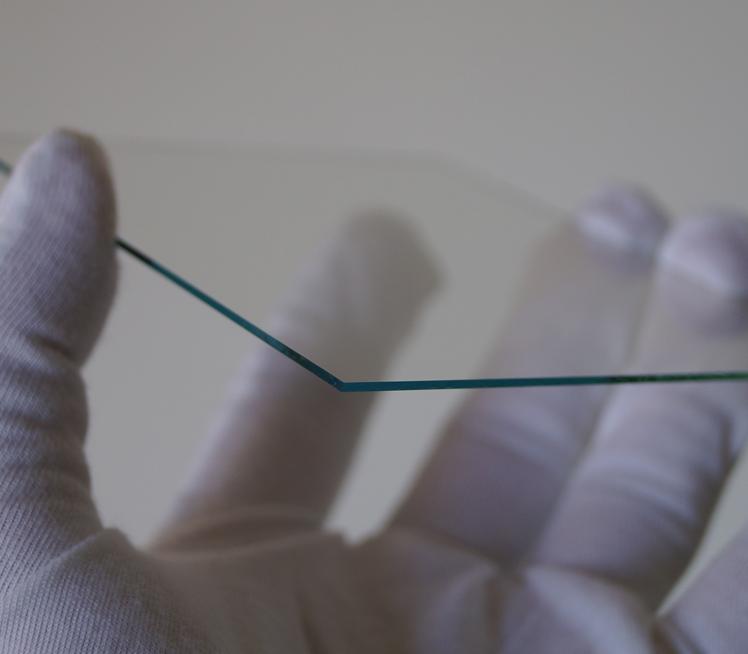

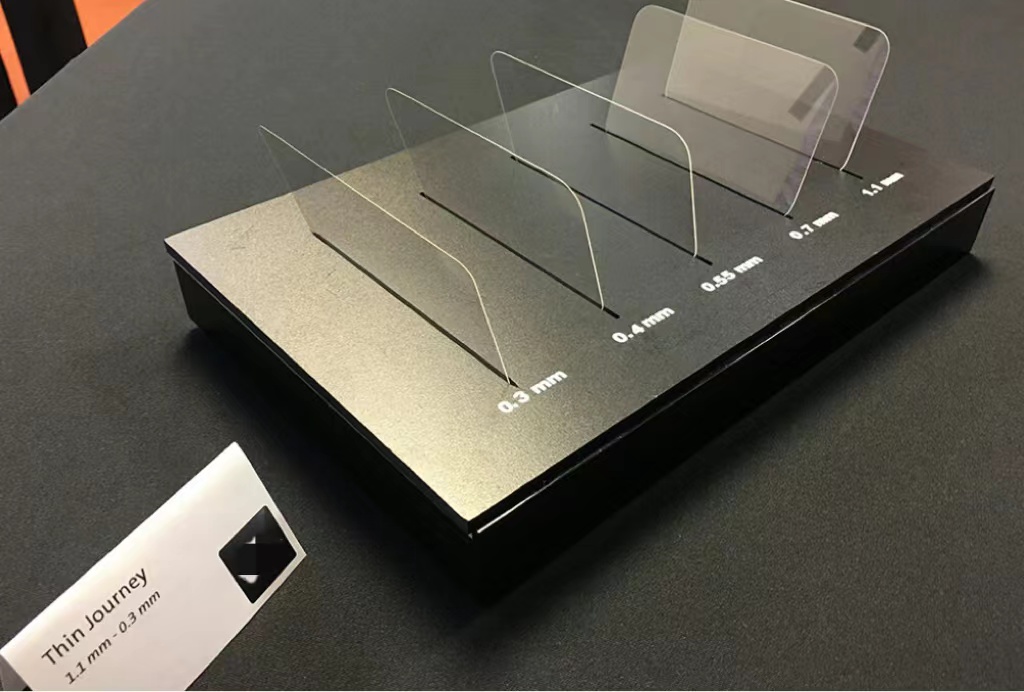

Thin Tempered Aluminosilicate Glass Substrate

These substrates are typically less than 1mm thick and are used in applications where weight and thickness are critical factors, such as in smartphones and tablets.

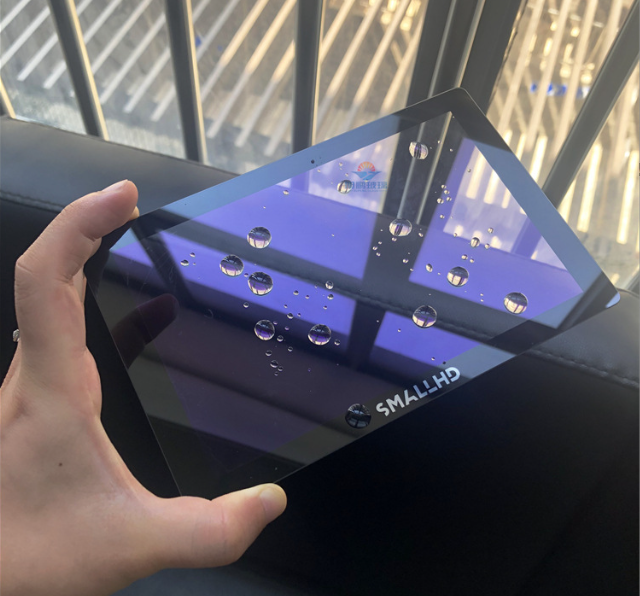

Coated Tempered Aluminosilicate Glass Substrate

These substrates come with various coatings like anti-reflective (AR), anti-glare (AG), and anti-fingerprint (AF), enhancing their optical and aesthetic properties.

Application-Specific Tempered Aluminosilicate Glass Substrate

These are designed for specific applications, like touch screen panels, solar panels, or automotive glass, each with its unique requirements.

How to Choose the Right Tempered Aluminosilicate Glass Substrate

Choosing the right tempered aluminosilicate glass substrate depends on your specific requirements, such as the application, the environment where it will be used, and the performance criteria it needs to meet.

Tempered Aluminosilicate Glass Substrate Tips/best practices

When dealing with tempered aluminosilicate glass substrate, handle with care to avoid surface damage, which could compromise its strength. Also, choose a reputable supplier like Tibbo, a leading manufacturer and supplier in China with strong expertise and extensive experience in the field.

Tempered Aluminosilicate Glass Substrate Tools

Various tools are used in the production and application of tempered aluminosilicate glass substrate, from high-precision grinding and polishing machines to coating and inspection equipment. At Tibbo, we employ state-of-the-art equipment to ensure that our products meet the highest quality standards.

Start With Tempered Aluminosilicate Glass Substrate Today

With the rapid advancement of technology, the demand for high-quality tempered aluminosilicate glass substrate is on the rise. Whether you’re an engineer, a product designer, or a business owner in the tech industry, understanding and utilizing this material can bring significant advantages.

Founded in 2014, Dongguan Tibbo Glass is a professional manufacturer and exporter specializing in the production of high-quality tempered aluminosilicate glass substrates. Our products are not only popular in China but also exported to various regions worldwide, including Europe, North America, India, and the Middle East.

With our advanced equipment and experienced team, we are committed to providing our customers with the best products and services. If you’re interested in learning more, check out our previous blog post on tempered borosilicate glass substrate.

To succeed in the competitive world of B2B export business, it’s crucial to choose a reliable and experienced supplier. At Tibbo, we’re proud to be a trusted partner for businesses around the world, providing high-quality products and excellent customer service. Our strong manufacturing capabilities, combined with our commitment to quality and innovation, make us a leading choice in the industry.

In the realm of tempered aluminosilicate glass substrate, the versatility, durability, and superior performance of this material make it a critical component in many high-tech applications. As we continue to advance and innovate in this field, we at Tibbo are excited to be part of this journey, driving progress and facilitating breakthroughs.

Whether you’re just starting to explore the world of tempered aluminosilicate glass substrates or looking to deepen your understanding, we hope this guide has been helpful. As always, we’re here to assist with any questions or needs you may have. We invite you to visit our website to learn more about our products and services. Together, let’s unlock the potential of tempered aluminosilicate glass substrate.