Introduction to Conductive Glass

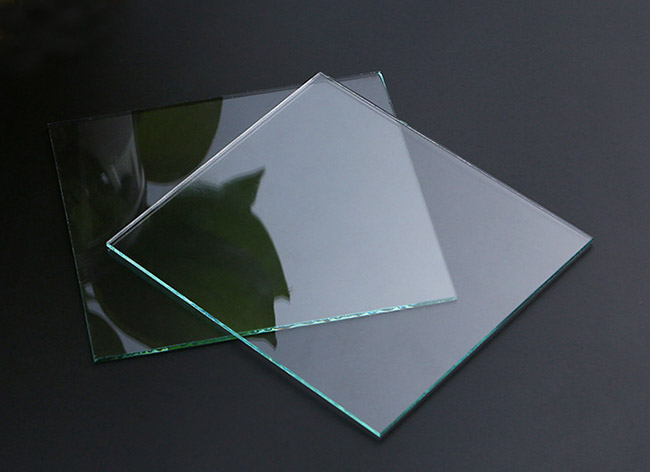

Conductive glass, is a kind of glass with low resistance and can conduct electricity. Conductive glass is divided into two kinds of volume conductive glass and surface conductive layer glass. Volume conductive glass contains alkaline oxides, silicon oxide, titanium oxide in its composition. Surface conductive layer glass is made by vaporizing a metal film (e.g., gold, platinum, etc., with a thickness of less than 10 millimeters) on a transparent glass surface, or spraying a metal oxide conductive film (e.g., tin, indium, etc.) on a heated glass surface.

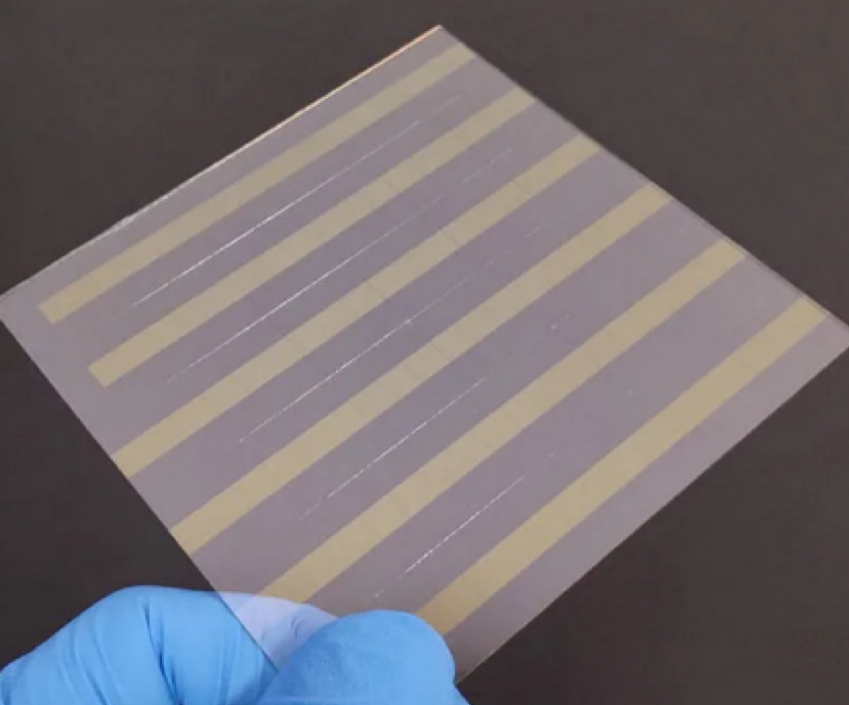

ITO conductive glass is based on sodium-calcium-based or silicon-boron based substrate glass, the use of magnetron sputtering method coated with a layer of indium tin oxide (commonly known as ITO) film processed into. In the flat panel display industry is mainly used in the field of touch screen and liquid crystal panel.

ITO conductive glass characteristics:

1, alkali resistance. Alkali-resistant is immersed in 60 ℃, the concentration of 10% sodium hydroxide solution for 5 minutes, ITO layer square resistance change value does not exceed 10%.

2, acid resistance. Acid resistance is immersed in 25 ℃, concentration of 6% hydrochloric acid solution for 5 minutes, ITO layer square resistance change value does not exceed 10%.

3, solvent resistance. Solvent resistance in 25 ℃, acetone, anhydrous ethanol or 100 parts of deionized water plus 3 points EC101 formulated cleaning solution for 5 minutes, ITO layer square resistance change value does not exceed 10%.

4, adhesion. In the tape attached to the surface of the film layer and quickly tear off, the film layer without damage; or even after tearing three times, the ITO layer square resistance change value does not exceed 10%.

5, stability. At 300 ° C in the air, after heating for 30 minutes, ITO conductive film square resistance value should not be greater than 300% of the original square resistance.

FTO conductive glass characteristics:

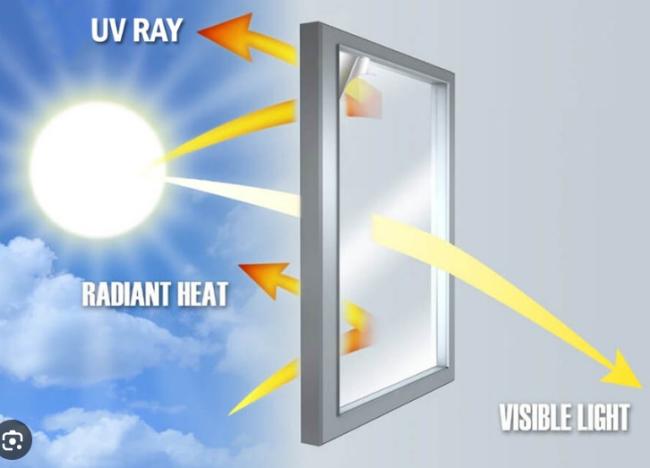

FTO conductive glass for fluorine-doped SnO2 transparent conductive glass (SnO2: F), referred to as FTO. FTO glass is developed and utilized as a replacement for ITO conductive glass, which can be widely used in the fields of liquid crystal display, photocatalysis, thin film solar cell substrate, dye sensitized solar cells, electrochromic glass.

FTO glass can be used as a replacement for ITO conductive glass, widely used in LCD, photocatalysis, thin film solar cell substrate, etc., the market demand is great.

FTO conductive glass features: low square resistance, high light transmission, large area, light weight, easy to process, impact resistance.

Warm notice for using

1, only touch the four sides of the pick and place, can not touch the conductive glass ITO surface.

2, light take and put, can not collide with other fixtures and machines.

3, if you want to store for a long time, be sure to pay attention to moisture, so as not to affect the resistance of the glass and transmittance; stored at room temperature, humidity below 65% dry and cool, avoid direct sunlight.

4, at any time do not allow stacking; conductive glass is generally required to be placed vertically; flat operation, try to keep the ITO face down; thickness of 0.55mm or less glass can only be placed vertically;.

ITO/FTO glass cleaning

ITO/FTO conductive glass in the production, packaging, transportation process. Glass surface may be dust, grease and other impurities contamination, in the use of ITO/FTO conductive glass before cleaning is a must for the preparatory work. Cleaning party has a variety of forms, which is commonly used in the use of organic solvents ultrasonic cleaning. Glass surface contamination of grease is insoluble in water, but it can be dissolved in toluene, acetone, ethanol and other organic solvents.

Among them, toluene has the strongest ability to remove oil, so first cleaned with toluene, but toluene can not be left on the surface of the glass. Because toluene is soluble in acetone, can be cleaned with acetone, not only can the residual oil and grease cleaned off, at the same time, toluene is also dissolved. Similarly, acetone can not be left on the glass surface. Since acetone is soluble in ethanol, it can be cleaned with ethanol again. Ethanol and water to any proportion of mutual solubility, and then a large number of deionized water to dissolve the ethanol, and then put into the anhydrous alcohol to save, use and then take out to use, so that you can one-time cleaning of many tablets.

Because of these general: toluene (10-20min) → acetone (10-15min) → ethanol (10-20min) → deionized water (20-30min) in the order of ultrasonic cleaning → anhydrous alcohol preservation (long time storage and then take out). In this way, good results can be received.

Send inquiry to us : https://tibboglass.com/contact-us/

Tibbo Instragm : https://instagram.com/tibboglass?igshid=OGQ5ZDc2ODk2ZA==

Tibbo Facebook: https://www.facebook.com/profile.phpid=61550780595281&mibextid=LQQJ4d