FTO conductive glass and ITO conductive glass seems to be a pair of twins, the name is only a difference of one character, but also are a kind of conductive glass. So, you may ask: what is the difference and connection between FTO glass and ITO glass, can they replace each other?

To answer this question, we may have to answer from the following 7 aspects for ITO and FTO Glass :

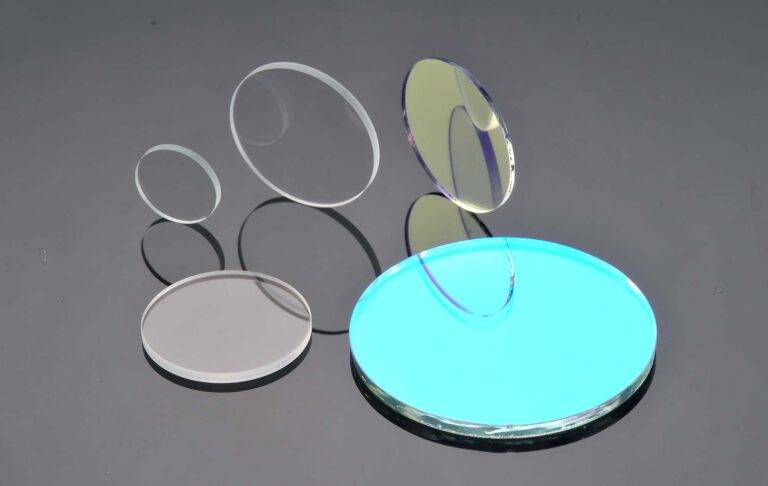

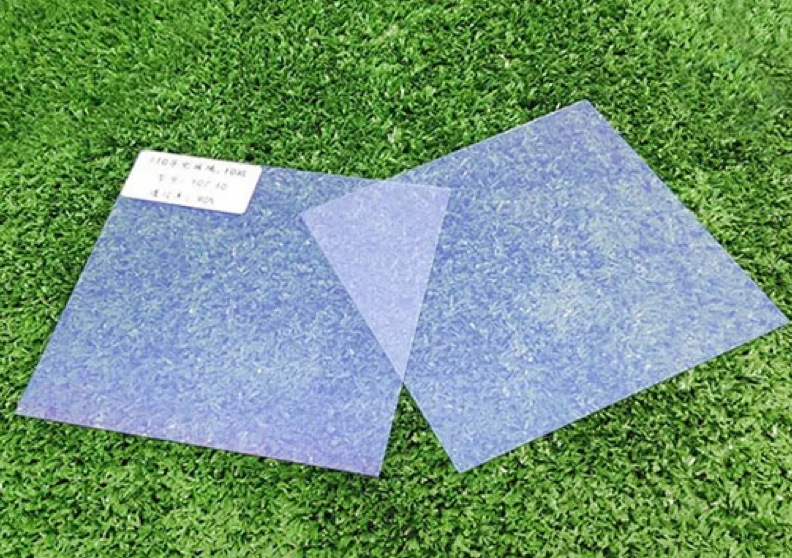

ITO conductive glass

ITO coated glass is a very mature product with high transmittance, firm film layer, good conductivity, etc. It was initially used in the front electrode of photovoltaic cells. However, with the improvement of light absorption performance requirements, TCO glass must have the ability to improve light scattering, and ITO coating is difficult to do this, and laser etching performance is also poor. Indium is a rare element, less storage in nature, the price is higher, ITO applied to solar cells in the plasma is not stable enough, so ITO coating is not the mainstream electrode glass for photovoltaic cells.

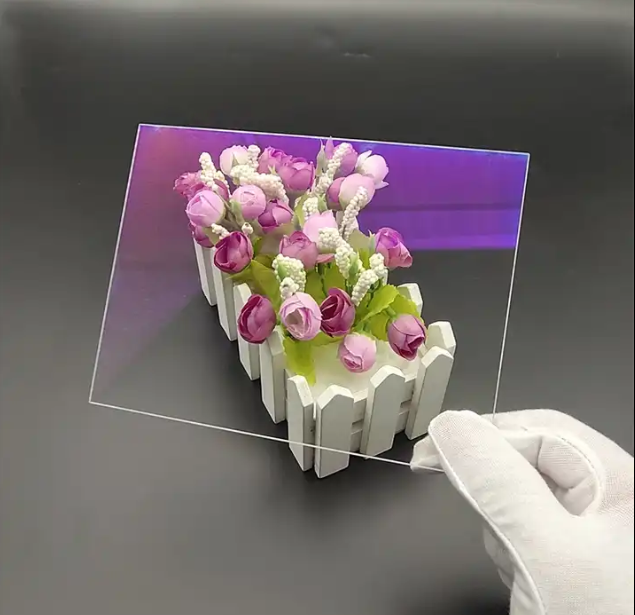

FTO coating glass

SnO2 coating, also referred to as FTO, is mainly used in the production of architectural Low-E glass. Its conductivity is slightly worse than ITO, but it has the advantages of relatively low cost, easy laser etching, and suitable optical properties. By upgrading and improving the production technology of ordinary Low-E, products with better conductivity than ordinary Low-E and with haze have been manufactured. TCO glass produced by utilizing this technology has become a mainstream product for thin film photovoltaic cells.

The difference between ITO &FTO glass

ITO glass

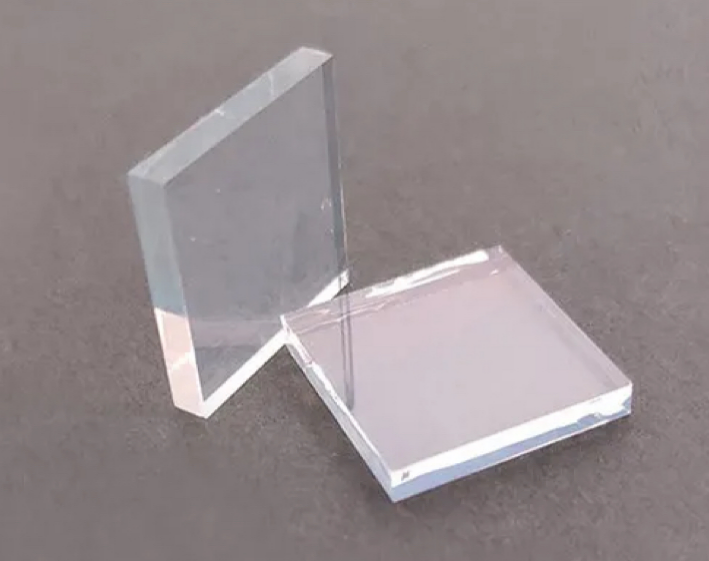

1, definition-wise, the two have different coating layer compositions.

ITO conductive glass refers to the sodium-calcium-based or silicon-boron based substrate glass on the basis of the use of magnetron sputtering method coated with a layer of indium tin oxide film processed glass. FTO conductive glass refers to fluorine-doped tin dioxide conductive glass.

2, conductive properties, ITO glass conductivity is better than FTO glass, FTO glass if not specially treated, its laminated surface barrier is high, not easy to transmit electrons;

FTO glass

3, cost cost, FTO glass cost is lower than ITO glass;

4, in terms of etching difficulty, the etching process of FTO glass is easier than that of ITO glass;

5, high temperature resistance, FTO glass is better than ITO high temperature resistance, the former can be up to 700 degrees;

6, FTO glass sintering after the square resistance change is relatively small, than with ITO glass to do the printing electrode when the sintering effect is good;

7, transmittance, FTO glass square resistance value is large, low transmittance rate, ITO glass transmittance rate is higher.

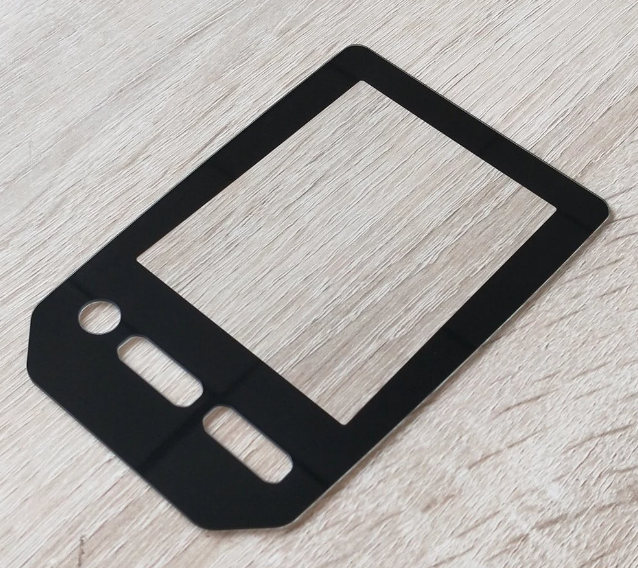

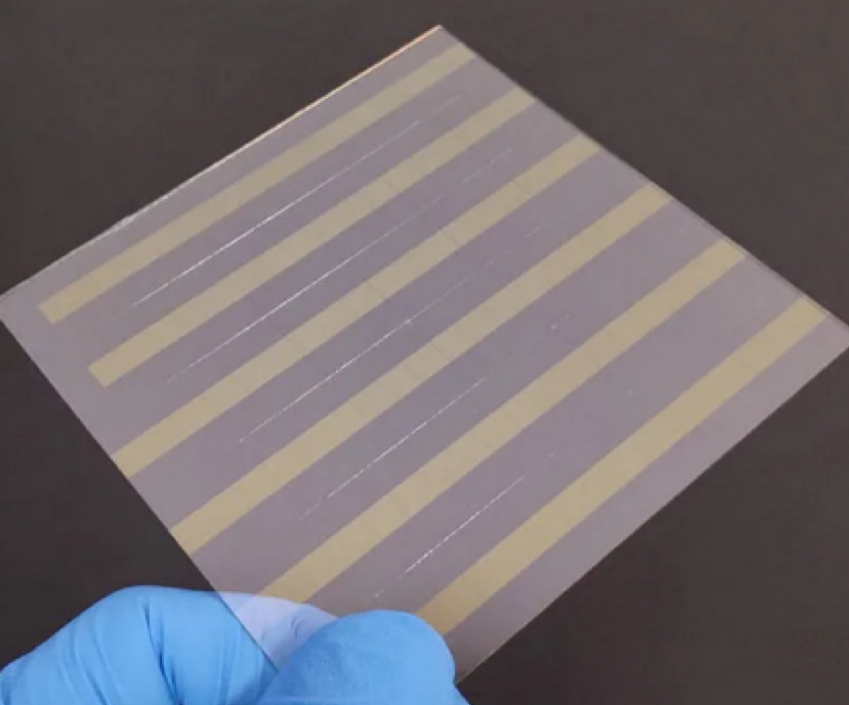

Conductive film glass – laser etching

Of course, although there are many differences between the two, but also have to say that in some areas, FTO glass can be used as a substitute for ITO glass, such as liquid crystal display, photocatalysis, thin film solar cell substrate and other fields. With special treatment of FTO glass, can be realized with ITO glass is very close to the effect, but the cost will be significantly reduced.

Well, above is our opinions for the differences and connections between FTO coating glass and ITO coating glass , hope it could help you to chose them.

Send inquiry to us : https://tibboglass.com/contact-us/

Tibbo Instragm : https://instagram.com/tibboglass?igshid=OGQ5ZDc2ODk2ZA==

Tibbo Facebook: https://www.facebook.com/profile.phpid=61550780595281&mibextid=LQQJ4d