Introduction

In today’s highly digital world, touch screen glass panels have become ubiquitous across countless devices and systems. From smartphones and tablets to interactive kiosks, appliances, and more, touchscreens allow intuitive and seamless user experiences. But what exactly are these touch screen glass panels? How do they work their ‘magic’? This article provides a comprehensive look at what touch screen glass is all about.

What is Touch Screen Glass?

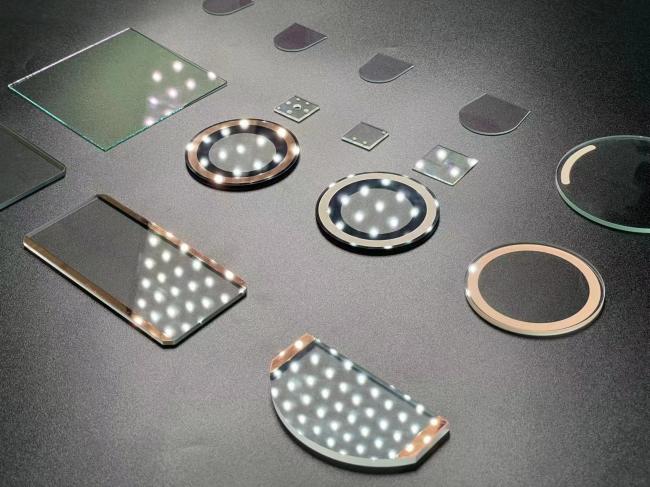

Touch screen glass, also called touch panel glass, refers to a specialized glass product that allows touch-based user input and interaction. It comprises a glass substrate coated with a transparent, conductive layer like ITO (Indium Tin Oxide) or FTO (Fluorine-doped Tin Oxide).

The conductive coating enables touch sensitivity – when a finger or stylus touches the screen, it causes a change in the electrical current at that point, registering the touch event. The controller processes the inputs and converts them into commands to control the device functions.

Types of Touch Screen Glass Technologies

There are several touch screen technologies leveraging different working principles:

1. Resistive Touch Screens

These have two layers – a flexible conductive top layer and a rigid conductive bottom layer separated by insulating dots. Touch compresses the layers to make contact and enable touch detection. Low cost but reduced clarity.

2. Capacitive Touch Screens

Have a glass coated with ITO. Touch disrupts the electrostatic field to initiate touch response. High clarity, durable, but costlier. Two types – surface capacitive needs bare finger touch, projected capacitive works with fingers, stylus, gloves.

3. Infrared Touch Screens

Have infrared LED beams crisscrossing the frame. Touch obstructs beams, triggering response. Medium cost and clarity. Stylus or finger works.

4. Surface Acoustic Wave

Touch reflects/absorbs ultrasonic waves on the glass to detect touch location. High clarity, sensitive, but requires advanced hardware.

Construction and Composition

Touch screen glass construction varies but broadly comprises:

- Glass substrate – Forms the main structural layer. Made of materials like soda lime, alkali aluminosilicate, borosilicate glass.

- Transparent conducting layer – Usually ITO or FTO for touch sensitivity. May also have additional coatings.

- Adhesive layers – Like optical clear resin to bond glass layers.

- Protective coating – Added for durability and resilience like AF/AR/AG coating.

Benefits of Touch Screen Glass

There are several benefits driving the immense popularity of touch screen glass:

- Intuitive, seamless user experience

- Sleek, futuristic device designs

- Versatility to support diverse touch gestures

- Durable and resilient for long product life

- High optical clarity for vivid visuals

- Smooth feel and response to touch interactions

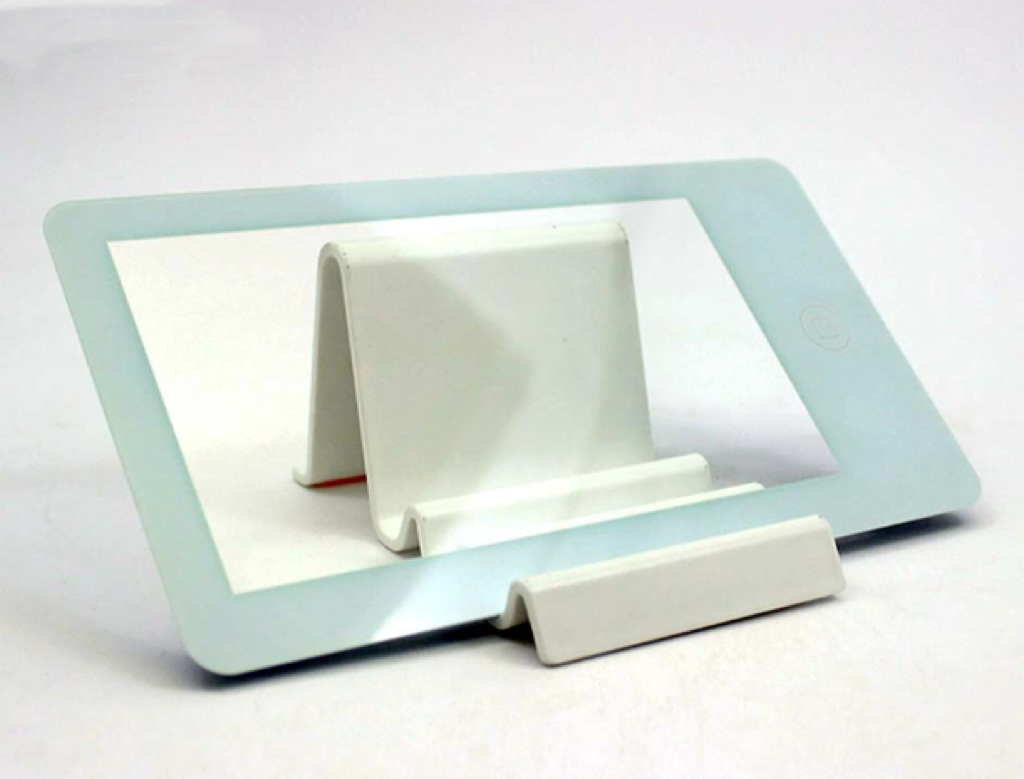

As touchscreens continue revolutionizing our digital experiences, touch screen glass remains an indispensable component enabling this ubiquitous technology. With their expertise and innovative capabilities, leading touch screen manufacturers like Tibbo Glass are positioned to advance touch technology further.

Explore Tibbo’s range of custom glass products including specialized touch screen glass engineered leveraging German and Swiss engineering. Learn more about the company’s capabilities and offerings on the Tibbo Glass website. For your touch screen requirements, get in touch with the experienced team at Tibbo Glass.

Gain additional insights into high-performance anti-bacterial glass by reading this detailed article.